Brazing Product list

Equipped with an infrared lamp heating furnace, in addition to being clean and quick heating and cooling, it can also be used for precise temperature control and gas atmosphere as desired. In addition to heating by brazing temperature control and low oxygen concentration atmosphere vaporization, which is indispensable for brazing research and development, real-time observation can be made of how the material melts and spreads during heating.

-

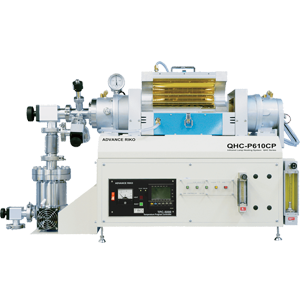

Infrared Lamp Heating System QHC series/Variable Atmosphere Lamp Heating System VHC series

Helping process development From solar cells to compound semiconductors. Combining an Infrared Gold Image Furnace and temperature controller, the QHC/VHC series is a compact high speed heating/ cooling system equipped with a quartz heat treatment chamber. The system is customizable to your needs.

-

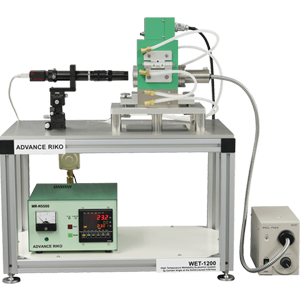

Hight Temperature Wettability Evaluation System by Contact Angle at the Solid-Liquid Interface WET-1200

Capable of precise observations of substrate and ingot wettability This system has been commercialized as a compact, low-cost high-temperature wettability test/contact angle measurement system based on the wettability test/contact angle measurement system delivered to the Japan Aerospace Exploration Agency in 1993. This system can perform measurements by the static drop method. The extruded liquid drop method is also available(optional).