1. Why inspection is necessary?

Various parts and units could be getting dirty and deteriorated. Continuing to use the equipment in such a condition could lead to a failure of the device or poor performance.

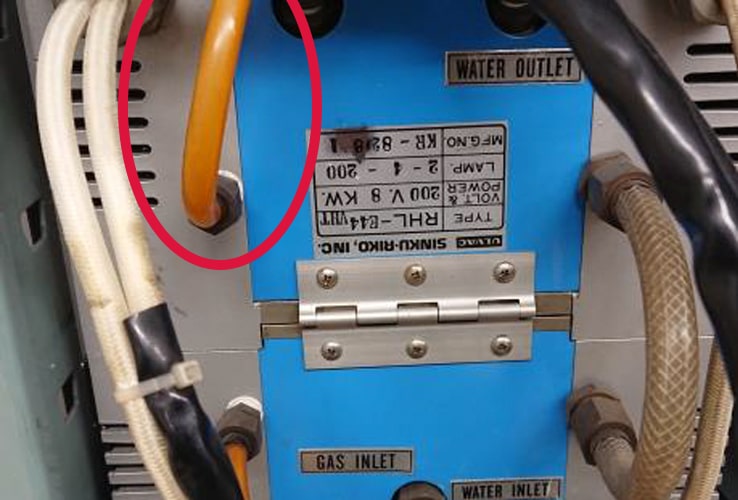

Infrared Gold Image Reactor RHL Series

Degradation of the cooling water hose

Damage / Water leakage

Laser Flash Method Thermal Constant Measurement System TC Series

Damage to the light shielding tube

unable to measure

Regular inspection of the equipment

Regular inspections are recommended to ensure long-term use of the equipment. We will propose an inspection plan, so please feel free to consult with us.

- ■Shortening the shutdown period of the equipment

Considering the possibility of the failures of the equipment and long lead items beforehand, the shutdown period of the equipment can be shortened.

We would recommend you to keep some backup stock of quartz parts and susceptors because they have a long lead time. - ■Equipment performance improvement

If the inside of the equipment is dirty, the equipment cannot perform as intended. It is recommended to clean the inside and replace dirty parts.

- ■Failure prediction by doing inspection

Only a manufacturer can see damage and thererefore prevent the equipment from being stalled.