Rapid cooling and water quenching Product list

Cooling control after heating by infrared lamps is important for control of material properties such as metals.

①A quick gas cooling mechanism that blows cooling gas directly onto the sample after heating can be installed.

②A water quench mechanism can be installed that enables the sample to drop into the aquarium after heating.

New materials can be developed, modified, and durability evaluated in the process of controlling rapid heating and cooling.

-

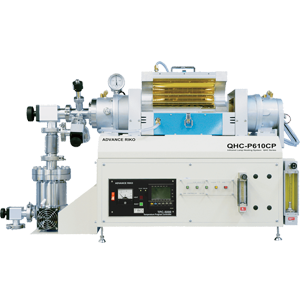

Infrared Lamp Heating System QHC series/Variable Atmosphere Lamp Heating System VHC series

Helping process development From solar cells to compound semiconductors. Combining an Infrared Gold Image Furnace and temperature controller, the QHC/VHC series is a compact high speed heating/ cooling system equipped with a quartz heat treatment chamber. The system is customizable to your needs.

-

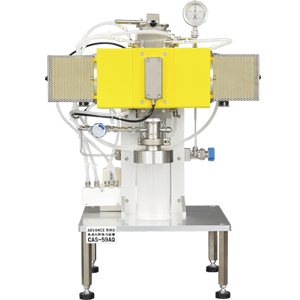

Rapid Heating / Water Quenching System CAS-59AQ

Rapid heating and quenching of materials This system is capable of water quench after heating. The maximum temperature is 1800°C under various atmospheres.

-

Continuous Annealing System for Steel Sheet CAS series

Easy determination of transformation point of steel sheets The CAS series achieves high-speed heating and cooling with the use of an Infrared Gold Image Furnace, direct temperature control of the samples, and easy atmosphere production. This system makes it possible to precisely achieve thermal treatment simulations of processes for steel and iron materials that had been previously difficult. Supports general purpose heat treatment tests to process heat treatment simulation tests of materials such as steel sheets, steel plates, stainless steel……