Thermoelectric materials and Peltier elements Product list

We follow with one-stop to the amount of power generated and the conversion efficiency of modules from basic research on thermoelectric materials, which are energy conversion materials for heat and electricity, . From bulk to thin flim as the shape of sample, we can provide the measurement methods to meet the needs of cutting-edge materials, such as magnetic materials and conductive polymers. For thermoelectric module evaluation system, it is available to follow from small modules of PN 1 pairs to large-size modules. In addition to thermoelectric materials, it is available to follow Peltier elements evaluation system.

-

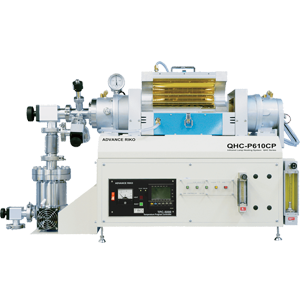

Infrared Lamp Heating System QHC series/Variable Atmosphere Lamp Heating System VHC series

Helping process development From solar cells to compound semiconductors. Combining an Infrared Gold Image Furnace and temperature controller, the QHC/VHC series is a compact high speed heating/ cooling system equipped with a quartz heat treatment chamber. The system is customizable to your needs.

-

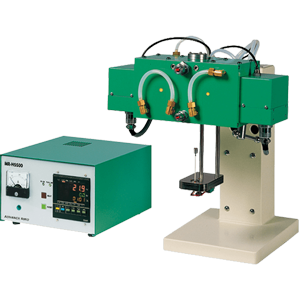

Spot Focused Infrared Gold Image Furnace System series

Heating up to 1800°C in just 1 min. For ultra-high temperature vacuum heat treatment MIRO series is a compact spot focused Gold Image Furnace which enables to heat up to 1800°C with extremely high reflection efficiency in combination with single or double type chambers.

-

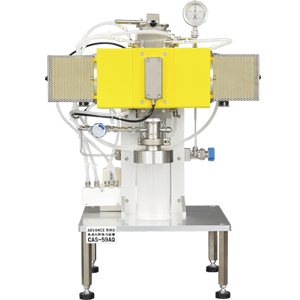

Rapid Heating / Water Quenching System CAS-59AQ

Rapid heating and quenching of materials This system is capable of water quench after heating. The maximum temperature is 1800°C under various atmospheres.

-

High Temperature Rapid Thermal Annealing System HT-RTA59HD

Heating a small piece of sample up to 1800°C just in 10 seconds. HT-RTA59HD is a desktop-type lamp annealing system which enables a small piece of sample to heat up to 1800°C (Ultrahigh temperature zone) just in 10 seconds with high reflection efficiency by spot focused heating.

-

Arc Plasma Source APS-1

Simultaneous deposition of different “targets” By adding this source to APD series or your vacuum chamber, different “targets” can be deposited simultaneously and materials with new characters can be produced.

-

Arc-Plasma method nano-particle Deposition System APD series

New nanoparticle deposition system using pulse vacuum arc discharge Pulse vacuum arc deposition is a unique technique to deposit ultrathin films and nanoparticles by generating metal ions in a simple process. This system can achieve high in terms of film flatness and particle fineness, which is impossible with other systems.