ADVANCE RIKO provides contract analysis services in the development of materials with new properties and in the development of materials with new functionality, as well as for the evaluation and research of heat characteristics and thermophysical properties of those materials.

In addition to the world’s de-facto standard system ZEM-3 series used for the current hottest topic, the evaluation of thermoelectric materials, thermoelectric efficiency of thermoelectric modules can also be evaluated.

For thermoelectric efficiency, many materials can be sampled, from thin films to bulk materials, and from metals to organic matter. Coefficient of thermal expansion measurements and infrared heating evaluation experiments are also possible.

Nanoparticle processes using arc plasma are perfectly suited to the research and development of catalysts and photocatalysts in fuel cells. In order to develop composite nanoparticles with the ability to dramatically increase their catalytic function, ADVANCE RIKO supports the sampling of nanoparticle films of various types of materials using arc plasma.

We can also handle custom sampling to support the varied needs of our customers. Please contact us about contract analysis needs.

thermal analysis / thermophysical property evaluation

| thermoelectric evaluation | Seebeck coefficient | It can be calculated by temperature difference between both ends of a samle which has temperature gradient in itself after being heated on its both ends with temperature gradient up to 50℃ and electromotive force in response to the temperature difference of the sample. |

|---|---|---|

| thermoelectric conversion efficiency | Apply temperature difference to thermoelectric module and then evaluate its power generation efficiency from current dependency on power generation amount and heat flow. | |

| thermal conductivity/thermal diffusivity | laser flash method | Laser flash method is used to measure thermal diffusivity of a sample from temperature rise on the backside of the sample after laser-pulse-heating the front side of the sample. |

| Xe flash method | Xe flash method is used to measure thermal diffusivity of a sample from temperture rise on the backside of the sample after xenon-pulse-heating the front side of the sample. | |

| scanning laser heating AC method | Scanning laser heating AC method / Apply a band of laser to the surface of a thin film sample periodically and then evaluate the thermal diffusivity of the sample in-plane direction. | |

| periodic heating method | Apply periodic heating to a sample and then evaluate the thermal diffusivity of the sample from the temperature behaviour caused by periodic temperature change. | |

| steady method | keep steady temperature gradient on a sample by applying higher temperature at one end of the sample and lower temperature at the other end and then calculate thermal conductivity after measuring the temperature. | |

| 2 omega method | By detecting thermal amplitude with thermo-reflectance method, thermal conductivity of an insulating film on the substrate can be measured in thickness direction. | |

| scanning thermal probe | Seebeck coefficient and thermal conductivity (in-plane direction ) can be measured. | |

| differential thermal analysis/differential thermogravimetric analysis | differential thermal analysis/differential thermogravimetric analysis | While a sample and its reference substance are going through an identical thermal cycle, mass difference and temperature difference of both materials are measured continuously to observe changes both physical and chemical of them. |

| thermal expansion measurement | pushrod displacement detector | Change of a sample after heated is passed through a quartz glass detector to a differential transformer, and then a sensor inside the transformer moves to show output fluctuation, which is calculated as expansion / contraction of the sample. |

| laser interferometry | A method to quantify thermal expansion by measuring expansion change of a sample caused by temperature change, which is regarded as amount of stripe’s movement by two beam interference. (double optical path Michelson interferometer) | |

| saturated vapor pressure measuerement | When a material is heated in a vacuum at a steady heating rate, the weight of the material decreases. With the weight loss caused by vaporing and the change of temperatuure, thermogravimetric curve is obtained and then able to calculate saturated vapor pressure and evaporation rate. |

gas analysis

| thermal desorption | The cold wall structure allows gas analysis to be done under the environment with high temperature and little gas emission. |

|---|

heating test

| heat treatment | Annealing and gas-quenching of materials ae available under various kinds of atmosphere. |

|---|---|

| wettability / contact angle | Wettability and contact angle can be measured. |

| high-temperature observation | Various conditions of materials can be observed like crystal transformation, deposition, solidification, molten state. |

microvial growth activity

| microbial activity measurement | Microbial activity can be evaluated from amount of heat generated by microbials which are placed inside a container equipped with heat detector. |

|---|

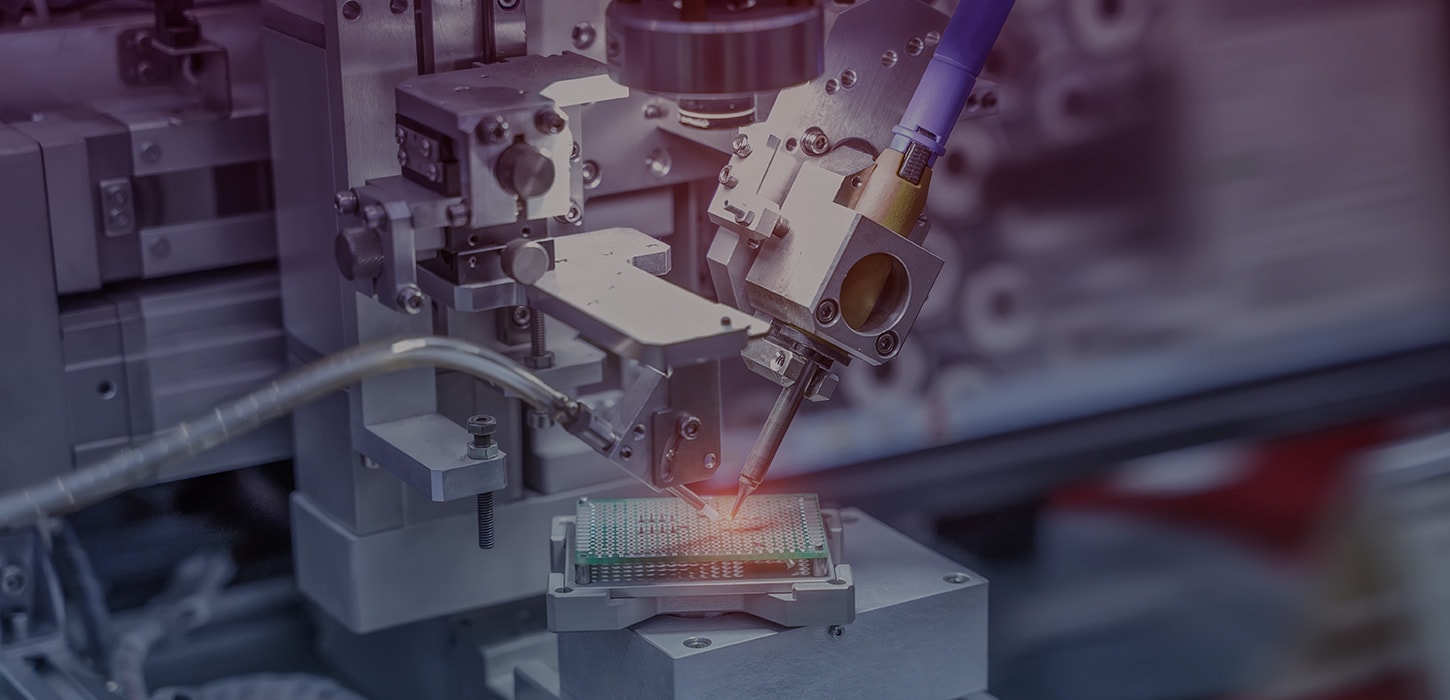

deposition test

| thin film coating/nano particle coating | Metal ions are created and then ultra thin films and nanoparticles are formed by pulse arc-deposition of the metal ions. The films’ flatness and particles’ finecess are satisfactory compared to those created by other methods. |

|---|

Custom-made sampling is also available. Please feel free to contact us.