Rapid heating Product list

Rapid heating can be achieved by radiation heating with the light of infrared lamps, and heating at a maximum temperature of 1800°C can be achieved by focusing the infrared light by gold reflective surface.

Precise temperature followability and temperature control by adjusting the output of lamps, and heating in vacuum, inert gas, ammonia and hydrogen, and ozone gas are possible.

It can contribute to process simulation in small sample and to tact time reduction in material research and production process. It also contributes to carbon neutrality from the viewpoint of energy loss.

-

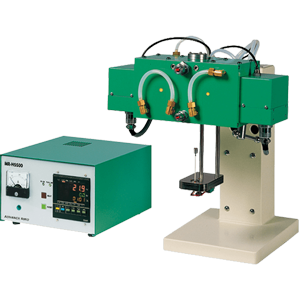

Spot Focused Infrared Gold Image Furnace System series

Heating up to 1800°C in just 1 min. For ultra-high temperature vacuum heat treatment MIRO series is a compact spot focused Gold Image Furnace which enables to heat up to 1800°C with extremely high reflection efficiency in combination with single or double type chambers.

-

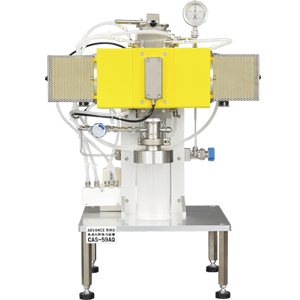

Rapid Heating / Water Quenching System CAS-59AQ

Rapid heating and quenching of materials This system is capable of water quench after heating. The maximum temperature is 1800°C under various atmospheres.

-

High Temperature Rapid Thermal Annealing System HT-RTA59HD

Heating a small piece of sample up to 1800°C just in 10 seconds. HT-RTA59HD is a desktop-type lamp annealing system which enables a small piece of sample to heat up to 1800°C (Ultrahigh temperature zone) just in 10 seconds with high reflection efficiency by spot focused heating.

-

Production Heat Treatment Furnace (Manufacturing Line Equipment)

Heationg system according to heat treatment objective This heating system is desiged based on the shape of the material and the heat treatment objective in the process. By making maximum use of high-speed heating, cooling and clean heating, we provide heating furnaces with non-polluting, low energy and high functionality.

-

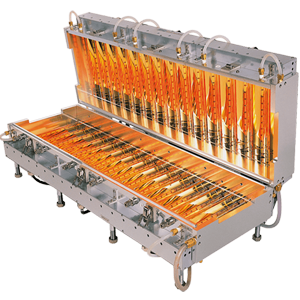

Continuous Annealing System for Steel Sheet CAS series

Easy determination of transformation point of steel sheets The CAS series achieves high-speed heating and cooling with the use of an Infrared Gold Image Furnace, direct temperature control of the samples, and easy atmosphere production. This system makes it possible to precisely achieve thermal treatment simulations of processes for steel and iron materials that had been previously difficult. Supports general purpose heat treatment tests to process heat treatment simulation tests of materials such as steel sheets, steel plates, stainless steel……