利用脉冲真空电弧放电形成纳米粒子的新型装置

脉冲真空电弧气相沉积是通过简单工艺产生金属离子以形成超薄膜和纳米粒子的唯一方法。

可以获得其它气相沉积方法无法获得的效果,例如膜的平坦度和细颗粒的形成。

用途

- APD-S(衬底沉积模型)

金属薄膜(磁性,等离激元,保护膜) - APD-P(粉末承载模型)

使用纳米颗粒的燃料电池催化剂、废气催化剂、光催化剂、公允值分解催化剂、碳纳米管催化剂及等离子体激元

特長

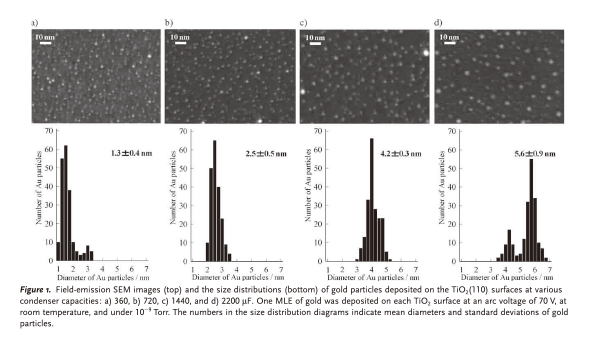

- 通过改变电容器的容量,可以自由选择纳米粒子的粒径约1.5 nm~6nm

- 任何导电材料(靶)都可以等离子体化

*靶比电阻0.01欧姆或更小 - 通过改变气氛,可以很容易地生成氧化物和氮化物

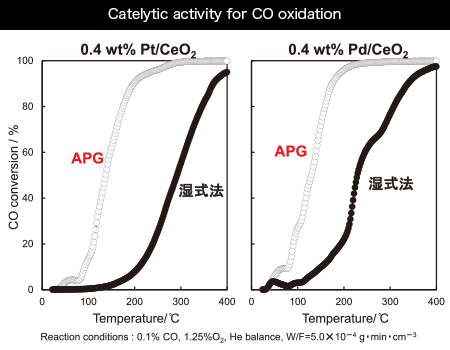

- 被承载的纳米粒子与湿式相比,显示了高活性的催化效果

仕様

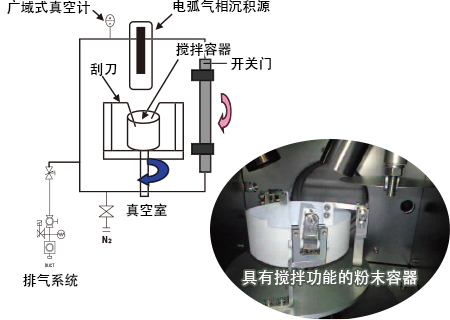

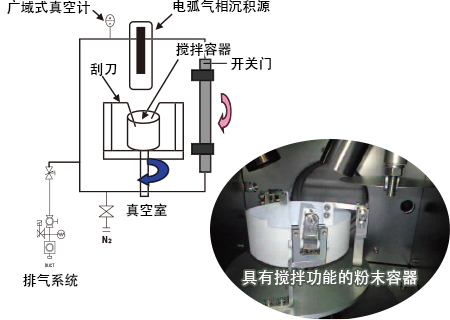

| 型式 | APD-S | APD-P |

|---|---|---|

| 样品尺寸 | 基板 2英寸 |

粉末 试样容器尺寸(内尺寸)φ95mm×高30mm带搅拌机构 |

| 标准气相沉积源数 | 1 | 1 |

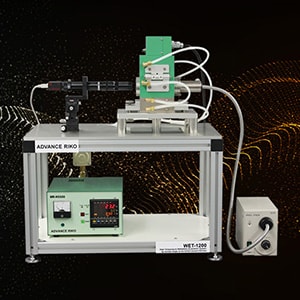

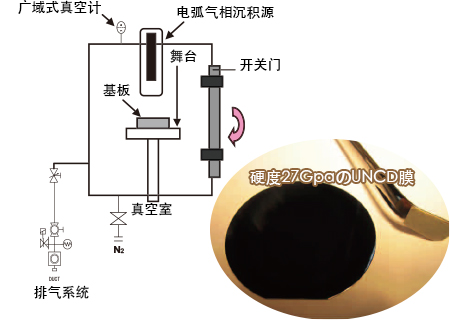

APD-P(粉末承载模型)

APD-S(衬底沉积模型)

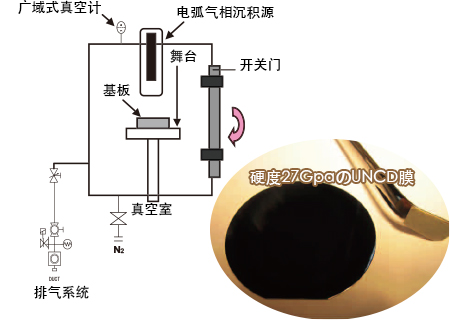

铁碳多层膜

由此可知,比例尺层压5纳米,铁(黑色部分)层压约1.5纳米。此时的速率约为0.075 nm/脉冲,因为成膜时间为20次1.5 nm。

由此可知,比例尺层压5纳米,铁(黑色部分)层压约1.5纳米。此时的速率约为0.075 nm/脉冲,因为成膜时间为20次1.5 nm。

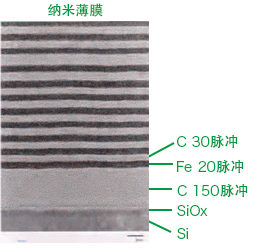

原理

动作图像

在施加高电位的靶上产生电弧后,储存在电容器中的电荷以脉冲方式瞬时放电,使靶材料成为等离子体,使电离的气相沉积粒子附着在衬底上。

5个特长

- 通过改变电容器的电容,纳米粒子的粒径可以自由选择约1.5 nm至6 nm。

- 任何导电材料(靶)都可以等离子体化。

*靶比电阻0.01欧姆或更小 - 通过改变气氛,可以很容易地生成氧化物和氮化物。当石墨在H2气体中放电时,它被转化为UNCD(超微晶金刚石)。

- 与湿式催化剂相比,本装置携带的纳米颗粒表现出更高的催化活性。

- APD-P型号携带粉末。APD-S型号由2in板承载。

※1、3、4については文献に依存します。

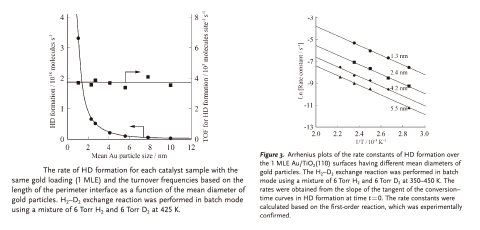

通过电弧等离子法负载在CeO2上的Pt及Pd催化剂,与传统湿法制备的催化剂相比,CO氧化活性更高

中所述修改相应参数的值。

引用文献:产业技术综合研究所环境化学技术研究部门藤谷忠博先生发表论文

引用文献:产业技术综合研究所环境化学技术研究部门藤谷忠博先生发表论文

电容器容量与纳米粒子形状的关系

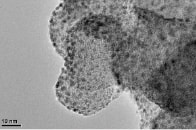

碳粉载Pt TEM图像

引用文献:産業技術総合研究所 環境化学技術研究部門 藤谷忠博様発表論文

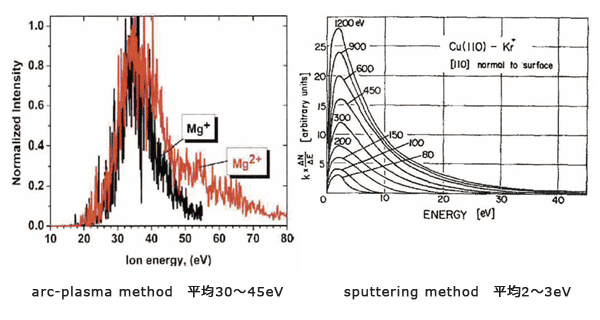

能量的差异对纳米粒子的生成和功能有很大的贡献(图表的纵轴是相对值,因此没有单位)

引用文献:电弧等离子体J.Apply.Phys.101(2007)043304 溅射J.Apply.Phys.35(1964)1819

论文清单

- C-dopand

MBE growth mode and C incorporation of GeC epilayers on Si (001) substrates using arc plasma gun as a novel C cource

Motoki Okinaka*, Yasumasa Hamana1, Takashi Tokuda, Jun Ohta, Masahiro Nunoshita

Journal of Crystal Growth 249 (2003) 78-86 - Characterisation of NPs by APD

Ultra-small platinum and gold nanoparticles by arc plasma deposition

Sang Hoon Kima,∗, Young Eun Jeonga, Heonphil Haa, Ji Young Byuna, Young Dok Kimb

Applied Surface Science 297 (2014) 52–58

10.1016/j.apsusc.2014.01.072 - HRTEM analyses of the platinum nanoparticles prepared on graphite particles using coaxial arc plasma deposition

Kun'ichi Miyazawa, Masaru Yoshitake, Yumi Tanaka

J Nanopart Res (2017) 19:191

10.1007/s11051-017-3895-6 - Characterisation of NPs by APD in ionic liquids

Temperature-independent formation of Au nanoparticles in ionic liquids by arc plasma deposition

Yoshikiyo Hatakeyama a,1, Satoshi Kimura b, Tatsuya Kameyama c, Yoshiaki Agawa d, Hiroyuki Tanaka d, Ken Judai a, Tsukasa Torimoto c, Keiko Nishikawa b,⇑

Chemical Physics Letters 658 (2016) 188–191

10.1016/j.cplett.2016.06.044 - CNT catalyst

High-density horizontally aligned growth of CNT with Conanoparticles deposited by Arc discharge plasma method

D. Phokharatkul,1 Y. Ohno,1,a H. Nakano,2 S. Kishimoto,1 and T. Mizutani1

APPLIED PHYSICS LETTERS 93, 053112 2008

10.1063/1.2969290 - Robust Noise Modulation of Nonlinearity in Carbon Nanotube Field-Effect Transistors

Toshio Kawahara , Satarou Yamaguchi, Kenzo Maehashi1, Yasuhide Ohno1, Kazuhiko Matsumoto1, and Tomoji Kawai1

Japanese Journal of Applied Physics 49 (2010) 02BD11

10.1143/JJAP.49.02BD11 - High-Rate Growth of Films of Dense, Aligned Double-Walled Carbon Nanotubes Using Microwave Plasma-Enhanced Chemical Vapor Deposition

Mineo HIRAMATSU, Hidetoshi NAGAO1, Masaki TANIGUCHI1, Hiroshi AMANO1, Yoshinori ANDO1 and Masaru HORI2

Japanese Journal of Applied Physics Vol. 44, No. 22, 2005, pp. L 693–L 695

10.1143/JJAP.44.L693 - Combinatorial

Combinatorial Arc Plasma Deposition of Thin Films

Seiichi HATA , Ryusuke YAMAUCHI1, Junpei SAKURAI1 and Akira SHIMOKOHBE1

Japanese Journal of Applied Physics Vol. 45, No. 4A, 2006, pp. 2708–2713

10.1143/JJAP.45.2708 - Combinatorial Search for Low Resistivity Pd–Cu–Si Thin Film Metallic Glass Compositions

Ryusuke YAMAUCHI , Seiichi HATA1, Junpei SAKURAI and Akira SHIMOKOHBE

Japanese Journal of Applied Physics Vol. 45, No. 7, 2006, pp. 5911–5919

10.1143/JJAP.45.5911 - Searching for Novel Ru-Based Thin Film Metallic Glass by Combinatorial Arc Plasma Deposition

Junpei SAKURAI , Seiichi HATA1, Ryusuke YAMAUCHI, and Akira SHIMOKOHBE

Japanese Journal of Applied Physics Vol. 46, No. 4A, 2007, pp. 1590–1595

10.1143/JJAP.46.1590 - Dye sensitizing

Transparent conductive oxide layer-less dye-sensitized solar cells consisting of floating electrode with gradient TiOx blocking layer"

Yoshikazu Yoshida,1 Shyam S. Pandey,1 Kenshiro Uzaki,1 Shuzi Hayase,1,a Mitsuru Kono,2 and Yoshihiro Yamaguchi2

APPLIED PHYSICS LETTERS 94, 093301 2009

10.1063/1.3089845 - Exhaust gas catalyst

CO oxidation activity of thermally stable Fe–Cu/ CeO2 catalysts prepared by dual-mode arc-plasma process

Satoshi Hinokuma,abc Noriko Yamashita,a Yasuo Katsuhara,a Hayato Kogamia and Masato Machida*ab

Catal. Sci. Technol., 2015, 5, 3945

10.1039/c5cy00370a - Nanoparticle catalyst preparation using pulsed arc plasma deposition

Satoshi Hinokuma,abc Satoshi Misumi,a Hiroshi Yoshidab and Masato Machida*ab

Cite this: Catal. Sci. Technol., 2015, 5, 4249

10.1039/c5cy00636h - Effect of thermal ageing on the structure and catalytic activity of Pd/CeO2 prepared using arc-plasma process

Satoshi Hinokuma,ab Hiroaki Fujii,a Yasuo Katsuhara,a Keita Ikeueab and Masato Machida*ab

Catal. Sci. Technol., 2014, 4, 2990

10.1039/c4cy00291a - Pd Fe/CeO2 bimetal catalysts prepared by dual arc-plasma deposition

Satoshi Hinokuma1, Yasuo Katsuhara, Eriko Ando, Keita Ikeue, Masato Machida∗

Catalysis Today 201 (2013) 92– 97

10.1016/j.cattod.2012.03.063 - Structure and catalytic property of supported rhodium catalysts prepared using arc-plasma

Satoshi Hinokumaa,b, MadokaOkamotob, ErikoAndob, KeitaIkeueb, MasatoMachidab,∗

Catalysis Today xxx (2011) xxx–xxx

10.1016/j.cattod.2011.03.008 - A nanometric Rh overlayer on a metal foil surface as a highly efficient three-way catalyst

Satoshi Misumi1, Hiroshi Yoshida1,2, Satoshi Hinokuma1,2,3, Tetsuya Sato4 & Masato Machida1,2

10.1038/srep29737 - Subnano-particle Ce catalyst prepared by pulsed arc-plasma process

Satoshi Hinokuma a,b,c, Hayato Kogami a, Noriko Yamashita a, Yasuo Katsuhara a, Keita Ikeue a,b, Masato Machida a,b,*

Catalysis Communications 54 (2014) 81–85

10.1016/j.catcom.2014.05.025 - Arc Plasma Processing of Pt and Pd Catalysts Supported on c-Al2O3 Powders

S. Hinokuma Æ K. Murakami Æ K. Uemura Æ M. Matsuda Æ K. Ikeue Æ N. Tsukahara Æ M. Machida

Top Catal (2009) 52:2108–2111

10.1007/s11244-009-9387-x - Fuel cell

Pt−Ni Nanoparticle-Stacking Thin Film: Highly Active Electrocatalysts for Oxygen Reduction Reaction

Naoto Todoroki,* Takashi Kato, Takehiro Hayashi, Shuntaro Takahashi, and Toshimasa Wadayama

ACS Catal. 2015, 5, 2209−2212

10.1021/acscatal.5b00065 - The d-Band Structure of Pt Nanoclusters Correlated with the Catalytic Activity for an Oxygen Reduction Reaction

Eishiro Toyoda,*,† Ryosuke Jinnouchi,† Tatsuya Hatanaka,† Yu Morimoto,† Kei Mitsuhara,‡ Anton Visikovskiy,‡ and Yoshiaki Kido‡

J. Phys. Chem. C 2011, 115, 21236–21240

10.1021/jp206360e - 2D Platinum Network ORR Catalyst on Carbon and Niobium Oxide Hybrid Support

C. Xu1, J. Yang1, B. L. Pence1, K. Gath1, P. Pietrasz1, M. Sulek1, K. Sun2, E. Sohm3, G. Meng3

ECS Transactions, 64 (3) 181-189 (2014)

10.1149/06403.0181ecst - Preparation of Pt/C Catalyst by Coaxial Arc Plasma Deposition for Polymer Electrolyte Membrane Fuel Cells

Yoshiaki Agawa,a,b,z Masayuki Kunimatsu,c Takeshi Ito,d Yasutaka Kuwahara,a and Hiromi Yamashitaa

ECS Electrochemistry Letters, 4 (10) F57-F60 (2015)

10.1149/2.0091510eel - Gold catalyst

Hydrogen Dissociation by Gold Clusters

Tadahiro Fujitani,* Isao Nakamura, Tomoki Akita, Mitsutaka Okumura, and Masatake Haruta

Angew. Chem. Int. Ed. 2009, 48, 9515 –9518

10.1002/anie.200905380 - Graphene layer growth catalyst

Graphene layer growth on silicon substrates with nickel film by pulse arc plasma deposition

K. Fujita,a) K. Banno, H. R. Aryal,b) and T. Egawa

APPLIED PHYSICS LETTERS 101, 163109 (2012)

10.1063/1.4761474 - Hydrogen peroxide solution

High performanceofhydrogenperoxidedetectionusingPt nanoparticles-dispersedcarbonelectrodepreparedbypulsedarc plasma deposition

Takeshi Ito a,n, MasayukiKunimatsu a, SatoruKaneko a, YasuoHirabayashi a, MasayasuSoga a, Yoshiaki Agawa b, KojiSuzuki c

Talanta 99(2012)865–870

10.1016/j.talanta.2012.07.048 - Magnetic thin film

Magnetic properties of Nd–Fe–B thick film magnets prepared by using arc deposition

M. Nakano, M. Sahara,a K. Yamawaki, T. Yanai, and H. Fukunaga

JOURNAL OF APPLIED PHYSICS 107, 09A744 2010

10.1063/1.3348233 - Nanocomposite Nd-Fe-B/α-Fe Thick-Film Magnets Prepared by Vacuum Arc Deposition

Masaki Nakano, Tomoaki Tsutsumi, Takeshi Yanai, and Hirotoshi Fukunaga

IEEE TRANSACTIONS ON MAGNETICS, VOL. 50, NO. 11, NOVEMBER 2014 - Photo catalyst

Improved Inactivation Effect of Bacteria: Fabrication of Mesoporous Anatase Films with Fine Ag Nanoparticles Prepared by Coaxial Vacuum Arc Deposition

H. Oveisi, S. Rahighi, X. J., Y.i Agawa, A. Beitollahi, S. Wakatsuki, and Y. Yamauchi

10.1246/cl.2011.420 - Prox catalyst

Support Effect of Arc Plasma Deposited Pt Nanoparticles/TiO2 Substrate on Catalytic Activity of CO Oxidation

Kamran Qadir,†,§ Sang Hoon Kim,‡,§ Sun Mi Kim,† Heonphil Ha,‡ and Jeong Young Park*,†

J. Phys. Chem. C 2012, 116, 24054−24059

10.1021/jp306461v - Catalytic activity of Au TiO2 and Pt TiO2 nanocatalysts prepared with arc plasma deposition under CO oxidation

Sang Hoon Kima,1, Chan-Ho Jungb,c,1, Nruparaj Sahub,c, Dahee Parkb,c, Jung Yeul Yund, Heonphil Haa, Jeong Young Parkb,c,∗

Applied Catalysis A: General 454 (2013) 53– 58

10.1016/j.apcata.2012.12.049 - Thermoelectric element

Fabrication by Coaxial-Type Vacuum Arc Evaporation Method and Characterization of Bismuth Telluride Thin Films

M. UCHINO,1 K. KATO,2 H. HAGINO,1 and K. MIYAZAKI1,3

Journal of ELECTRONIC MATERIALS, 2013 TMS

10.1007/s11664-012-2438-2 - TiN film

Synthesis of TiN thin film on diamond surface for ferrous metal contacts by a new atom beam method

Hiroshi Kinoshitaa,∗, Shunsuke Yamamotob, Hideaki Yatanib, Tetsuo Nakaic, Nobuo Ohmaeb

Applied Surface Science 258 (2012) 3002– 3006

10.1016/j.apsusc.2011.11.026 - Ultrananocrystalline Diamond/Hydrogenated Amorphous Carbon Composite Films

Structural and Physical Characteristics of Ultrananocrystalline Diamond/Hydrogenated Amorphous Carbon Composite Films Deposited Using a Coaxial Arc Plasma Gun

T. Yoshitake, Y. Nakagawa, A. Nagano, R. O., H. Setoyama1, E. Kobayashi1, K. Sumitani1, Y. Agawa and K. Nagayama

Jpn. J. Appl. Phys. 49 (2010) 015503