Ultra High Precision Thermal Expansion Measurement System by Laser Interferometer

SuperLIX

The world of expansion with accuracy of 1×10-8/K or less

Thermal expansion measurement with the world-class ultra high accuracy *as a commercial measurement system

Application case

- Development of zero-expansion materials

- Development of negative thermal expansion material and anode materials

- Development of standard materials

- Development of materials for actuator

Applications

- High-precision dilatometry of materials with extremely low expansion rate such as 10-8/K (glasses, ceramics, metal, etc.)

・ Spare parts of lithography system for semiconductor production

・ Spare parts of precision stage

・ Materials requiring high accuracy such as for aerospace industries

・ Materials for highly precise photogram substrate - Quality control of low expansion materials

Features

- By incorporating a elimination mechanism within the system, the impact of the vibration disturbance can be prevented, and the typical analytical electronic balance (resolution 0.01 mg) can be used in a stable environment. (patent application: 2016-058190, 058191, and 058192)

- Measure the displacement of a sample based on the laser wavelength (632.8nm). Stray light can be eliminated by integrating optical elements, improving the signal-to-noise ratio of fringe signals. No measurement or operation is required for special displacement calibration.

- The interference fringes are detected by the image sensor and imageprocessed to calculate the displacement (expansion/contraction) at a high resolution even during sample measurement. And the expansion rate can be checked.

Specifications

| Model | SuperLIX-R |

|---|---|

| Temperature range | Standard type 5~50℃ (highly accurate water circulation system used) |

| Sample size | φ5 or □5±0.5 x L20(mm) (standard sample sizeφ5xL20(mm), end-face finishing with R-shape) |

| Atmosphere | Reduced pressure He atmosphere |

| Measurement method | Dual path Michelson laser interferometry |

Utility

| Space requirement | Approx. W1200 xD760 x H1600(mm) *2500mm(H) or more space is required for removing a chamber. |

|---|---|

| Power | PC(monitor, desktop): AC100V 15A(plug and earth cable included), two locations Exhaust system: AC200V three phase 15A one location Gas feeding system: AC100V single phase 15A one location Water circulation system: AC100V 15A(plug and earth cable included) one location |

| Grounding | D type (ground resistance 100Ω or below) one location |

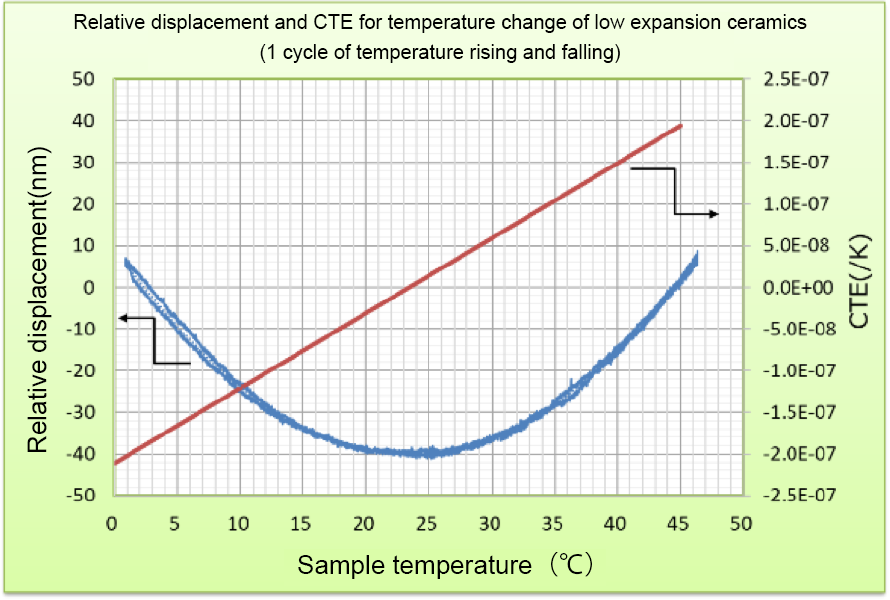

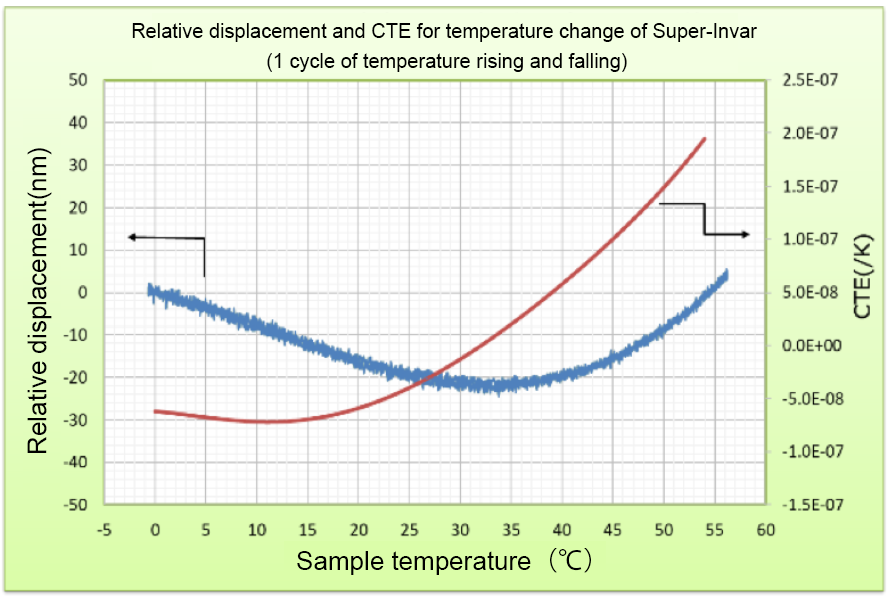

Measurement Example

Patents and standards

Compliant with JIS R3251-1990

Special Features 2016-058190, 058191, and 058192

Related product

Infrared lamp heating system RTP-mini

Thermal Flow Rate Evaluation System for Low Thermal Resistance Multilayer Substrates F-CAL

Ultra High Precision Thermal Expansion Measurement System by Laser Interferometer SuperLIX

Polymeric Thermoelectric Sheet Evaluation System ZEM-d

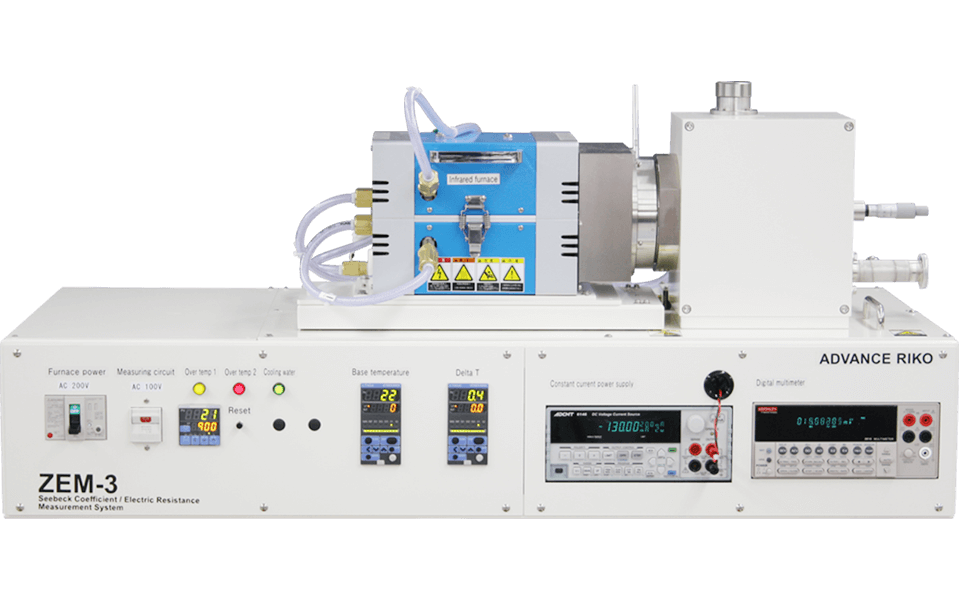

Seebeck Coefficient / Electric Resistance Measurement System ZEM-3 series

Atmospheric Thermoelectric Module Evaluation System F-PEM

Ultra High Precision Thermal Expansion Measurement System by Laser Interferometer SuperLIX Contact form

The information that you enter will only be used to provide you with a response. However, when you request that we mail you a catalog or other materials, please understand that the shipper specified by ADVANCE RIKO may use only the information necessary to send those materials, such as your name and address.

Please check our privacy policy for more details.