Carbon Product list

We can offer a variety of products ① Rapid heat treatment (2) Thermal expansion measurement ③ Thermal conductivity measurement ④ Electrical resistivity measurement ⑤ Observation and visualization in the heating process ⑥ Catalytic activity in supporting different metals on carbon, etc.,for the evaluation of various carbon materials (carbon fiber, fine carbon nanotube, CFRP, catalyst support, electrode material. Also, we can also offer the puffing evaluation system for graphite carbon.

-

Laser Flash Method Thermal Constant Measurement System TC-1200RH / TC-9000 series

Thermal conductivity measurements covering a wide range of materials not only thermoelectric materials but also metals, ceramics, carbon etc. The systems measure 3 thermal constants (Thermal diffusivity, Specific heat capacity, Thermal conductivity) for uniform solid materials such as thermoelectric materials, ceramics, carbon, Metal, etc

-

AC Method Thermal Diffusivity Measurement System LaserPIT

Thermal conductivity evaluation in-plane direction of films, thin sheets and thin films etc. This system can measure thermal diffusivity of sheet materials in-plane direction by scanning laser heating AC method (Angstrom method). About high thermal conducting films, sub-micron thin films can also be measurable.

-

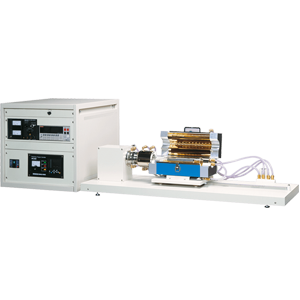

Rapid Multi Property Measurement System RMP-1

Heating up to 3000K within one second! This system measures thermophysical properties by applying current directly to a sample to heat up to higher temperature within one second. Measurable standard properties are electrical resistivity, total emissivity, specific heat capacity, thermal expansion rate and thermal diffusivity.

-

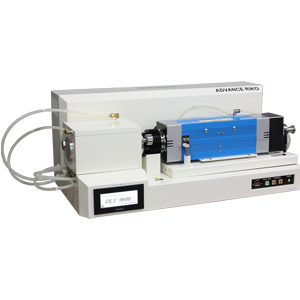

Electric Resistance Measurement System for Metals and Semiconductors TER series

Metallic phase transition, aging, recrystallization reaction This system can measure precisely the electric resistance of metallic alloys and semiconductors with DC four-thermal method.

-

Thermodilatometer DL-9000 / DLY-9000 series

Dedicated thermal expansion measurement system for bulk materials Dedicated linear expansion and contraction measurement system for various solid samples

-

Robotic Thermal Dilatometer DLY-9000 ROBOT

Labour-saving quality management with fully automatic and unattended operationuality control. This system was developed for the purpose of standardizing the measurement and saving labor in quality management. With superior repeatability, safety measures for unattended operation and chart function, this system is most suitable for quality management.

-

Arc Plasma Source APS-1

Simultaneous deposition of different “targets” By adding this source to APD series or your vacuum chamber, different “targets” can be deposited simultaneously and materials with new characters can be produced.

-

Arc-Plasma method nano-particle Deposition System APD series

New nanoparticle deposition system using pulse vacuum arc discharge Pulse vacuum arc deposition is a unique technique to deposit ultrathin films and nanoparticles by generating metal ions in a simple process. This system can achieve high in terms of film flatness and particle fineness, which is impossible with other systems.