Products list

-

Production Heat Treatment Furnace (Manufacturing Line Equipment)

Heationg system according to heat treatment objective This heating system is desiged based on the shape of the material and the heat treatment objective in the process. By making maximum use of high-speed heating, cooling and clean heating, we provide heating furnaces with non-polluting, low energy and high functionality.

-

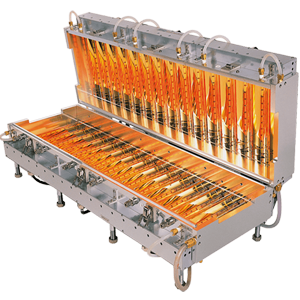

Continuous Annealing System for Steel Sheet CAS series

Easy determination of transformation point of steel sheets The CAS series achieves high-speed heating and cooling with the use of an Infrared Gold Image Furnace, direct temperature control of the samples, and easy atmosphere production. This system makes it possible to precisely achieve thermal treatment simulations of processes for steel and iron materials that had been previously difficult. Supports general purpose heat treatment tests to process heat treatment simulation tests of materials such as steel sheets, steel plates, stainless steel……

-

High Temperature Observation System TMS series

Vivid observations with image heating and the latest optical system Capable of observations of the crystal transformation, deposition, and solidification of metallic materials, capable of observations of the molten state and deposits of various materials, and capable of thermal cycle measurements of polymer materials from crystals → molten → re-solidification

-

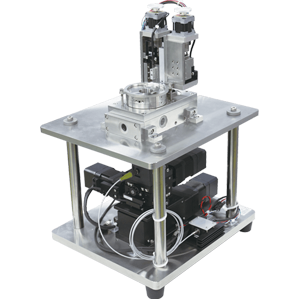

Micro-Indentation Tester μIT-1

With pressing a conical indenter against a small sample, creep behavior can be measured under high temperature. With the Micro-Indentation Tester based on new principles, this system does not require large samples like past systems.

-

Lateral Vibration Internal Friction Measurement System IFT series

Quantitative analysis of carbon and nitrogen in steel and iron This system measures the internal friction of steel and iron by the free vibration decay method.

-

Arc Plasma Source APS-1

Simultaneous deposition of different “targets” By adding this source to APD series or your vacuum chamber, different “targets” can be deposited simultaneously and materials with new characters can be produced.

-

Arc-Plasma method nano-particle Deposition System APD series

New nanoparticle deposition system using pulse vacuum arc discharge Pulse vacuum arc deposition is a unique technique to deposit ultrathin films and nanoparticles by generating metal ions in a simple process. This system can achieve high in terms of film flatness and particle fineness, which is impossible with other systems.

-

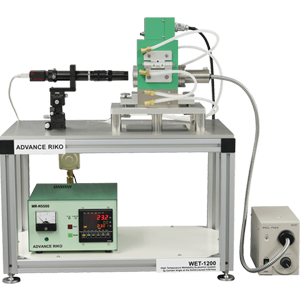

Hight Temperature Wettability Evaluation System by Contact Angle at the Solid-Liquid Interface WET-1200

Capable of precise observations of substrate and ingot wettability This system has been commercialized as a compact, low-cost high-temperature wettability test/contact angle measurement system based on the wettability test/contact angle measurement system delivered to the Japan Aerospace Exploration Agency in 1993. This system can perform measurements by the static drop method. The extruded liquid drop method is also available(optional).

-

Resonance Shear Measurement system RSM-1

This system can evaluate viscosity, friction, and lubrication characteristics in liquids at nano-scale thicknesses. This system can evaluate nanotribological behavior, viscosity, friction, and lubrication characteristics of liquids as a function of distance. Evaluations of electric double layer power, surface potential, adhesive force, adsorption characteristics, and intermolecular interaction

-

Twin-path Surface Force Apparatus RSM-SFA

Direct measurement of surface properties and interactions Unique system that can also handle opaque samples This system, coming from the existing Resonance Shear Measurement System [RSM-1] without the function to measure the resonance shear, focuses on the functions to measure the surface force. This system can measure the distance dependence of interactions and adsorption forcse produced between two surfaces. With the twin-path method (two-beam interferometry technique), measurement of opaque materials is also available and with the focused heating system (option),……