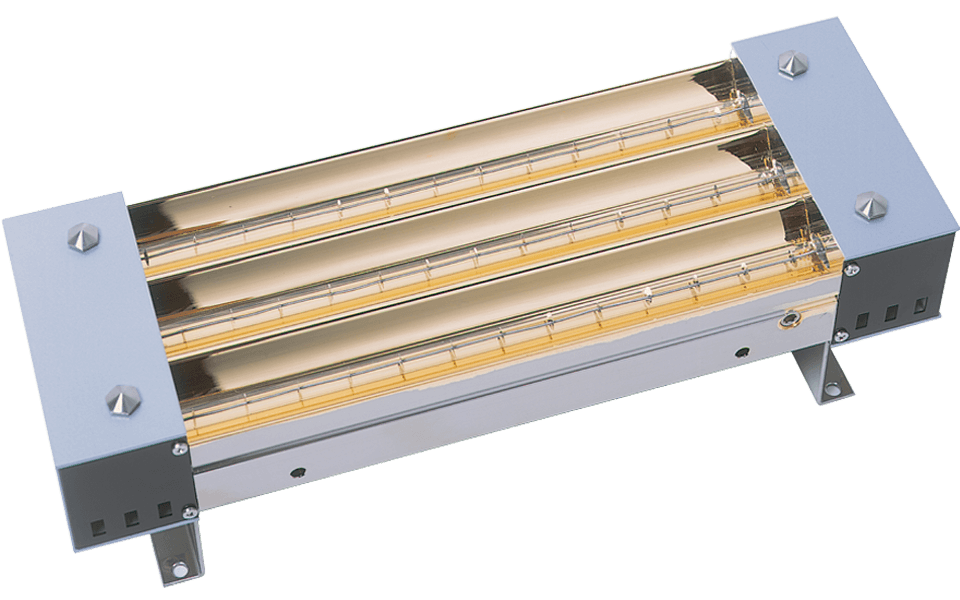

Infrared Gold Image Furnace

Ps, Pss series

Useable in wide fields from carbon nanotube growth equipment to production equipment.

The flat plate reflected infrared heating furnace can be used for applications such as a 2-inch to 300 mm diameter wafer lamp annealing system or a production baking furnace.

Applications

- The Ps type has 40-mm wide reflective surfaces.

- The Pss type has 20-mm wide reflective surfaces that allow high density lamp configurations.

- Both the Ps type and the Pss type can heat a wide area by increasing the number of reflective surfaces.

Features

- Heating large glass substrates (Solar cells, FPD, etc.).

- High-temperature, high-speed heating of semiconductor wafers.

- Annealing of thin steel sheets

Specifications

| Model*1 | Heating Method | Lamp Number | Heating Length (Light Emission length) |

Lamp Voltage | Input |

|---|---|---|---|---|---|

| Ps15V | Planar radiation heating | 1 | 140mm | 200V | 1.2kW |

| Ps110V | 265mm | 2.0kW | |||

| Ps116V | 420mm | 300V | 3.0kW | ||

| Ps35V | 3 | 140mm | 200V | 3.6kW | |

| Ps310V | 265mm | 6.0kW | |||

| Ps316V | 420mm | 300V | 9.0kW | ||

| Pss35V | 140mm | 200V | 3.6kW | ||

| Pss38V | 200mm | 4.8kW | |||

| Pss310V | 265mm | 6.0kW | |||

| Pss316V | 420mm | 300V | 9.0kW |

*1 Model number meaning

- For Ps(s)35V

- P : Parabolodial reflection , s : 40mm-width,(ss : 20mm-width) , 3 : Lamp number , 5 : Lamp length , V : Planar Heating type

・Please be aware that heating furnaces require cooling water.

・Heating temperature changes according to the heated sample’s infrared reflectance, absorption, heat capacity, and material.

・For other specification requirements, please feel free to contact us.

Related product

Infrared lamp heating system RTP-mini

Thermal Flow Rate Evaluation System for Low Thermal Resistance Multilayer Substrates F-CAL

Ultra High Precision Thermal Expansion Measurement System by Laser Interferometer SuperLIX

Polymeric Thermoelectric Sheet Evaluation System ZEM-d

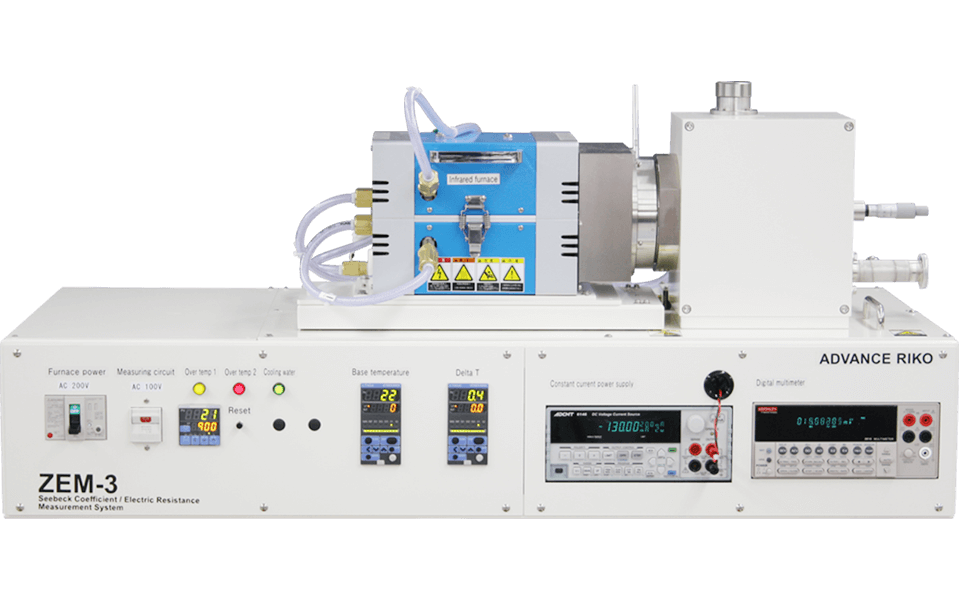

Seebeck Coefficient / Electric Resistance Measurement System ZEM-3 series

Atmospheric Thermoelectric Module Evaluation System F-PEM

Infrared Gold Image Furnace Ps, Pss series Contact form

The information that you enter will only be used to provide you with a response. However, when you request that we mail you a catalog or other materials, please understand that the shipper specified by ADVANCE RIKO may use only the information necessary to send those materials, such as your name and address.

Please check our privacy policy for more details.