Simplified Infrared Lamp Heating System

SSA series

Simplified system with Infrared Gold Image Furnace and a quartz chamber.

A low-cost heating system consist of an Infrared Golc Image Furnace and quartz chamber including a sample holder.

Applications

- Alloying of compound semiconductors

- RTA of Si, compound semiconductors

- Baking furnace for laminating materials on ceramic substrates

- Annealing furnace for glass and ceramic substrates

Features

- Quartz chamber is selectable from gas flow type or vacuum type. (Gas flow type is standard.)

- Gas flow type and vacuum type can be integrated as option.

- Simple input of temperature recipe into computer connected with USB

- Display temperature data on the PC monitor during heating

Specifications

| Model | SSA-E45P | SSA-E410P | SSA-P610CP |

|---|---|---|---|

| Heating Method | Focused light cylindrical heating | Focused light cylindrical heating | Parallel light cylindrical heating |

| Temperature Range | RT ~ 1400 °C | RT ~ 1200 °C | |

| Heating zone | φ15 × L50 (mm) | φ15 × L100 (mm) | φ50 × L100 (mm) |

| Soaking zone | φ10 × L40 (mm) | φ10 × L80 (mm) | φ40 × L80 (mm) |

| Heating chamber | Quartz chamber (φ30 mm) for gas flow |

Quartz chamber (φ98 mm) for gas flow |

|

| Sample holder | Quartz holder with boat shape | Quartz holder with boat shape | Quartz holder for 2-inch wafer |

| Thermocouple | JIS R-type | ||

| Temperature controller | TPC5000-32-1 | TPC5000-62-1 | |

*Heating temperature changes according to the heated sample’s infrared reflectance, absorption, heat capacity, and material.

Related product

Infrared lamp heating system RTP-mini

Thermal Flow Rate Evaluation System for Low Thermal Resistance Multilayer Substrates F-CAL

Ultra High Precision Thermal Expansion Measurement System by Laser Interferometer SuperLIX

Polymeric Thermoelectric Sheet Evaluation System ZEM-d

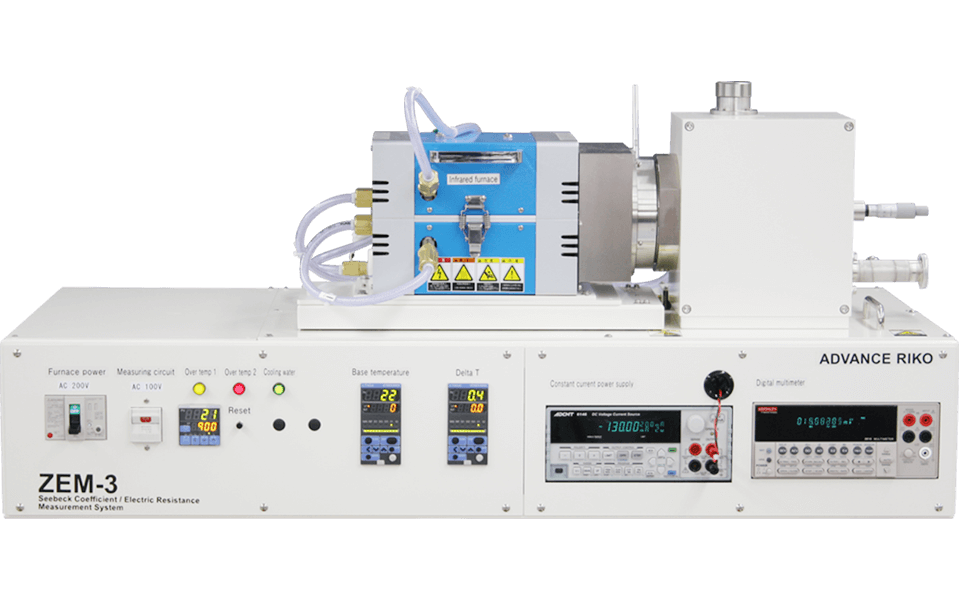

Seebeck Coefficient / Electric Resistance Measurement System ZEM-3 series

Atmospheric Thermoelectric Module Evaluation System F-PEM

Simplified Infrared Lamp Heating System SSA series Contact form

The information that you enter will only be used to provide you with a response. However, when you request that we mail you a catalog or other materials, please understand that the shipper specified by ADVANCE RIKO may use only the information necessary to send those materials, such as your name and address.

Please check our privacy policy for more details.