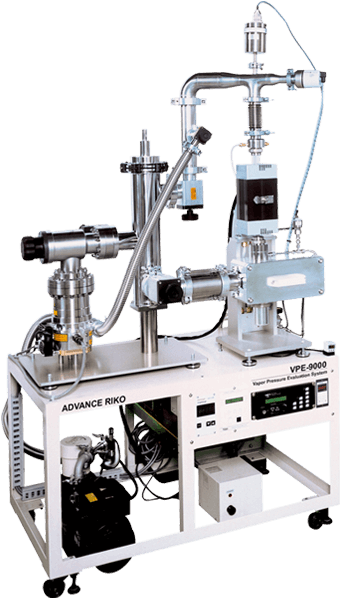

Vapor Pressure Evaluation System

VPE-9000<vacuum thermobalance>

Stable changes in weight in a high vacuum

This system evaluates saturated vapor pressure and the thermal behavior of organic materials. An exhaust method is employed that allows stable measurements even in a vacuum. Achieves precise temperature controllability and responsiveness with the Infrared Gold Image Furnace

Applications

- Measures the saturated vapor pressure of organic materials

- Sublimation purification simulations

- Measures changes in weight in a vacuum

Features

- Finds the evaporation conditions of polymer materials

- Changes in weight at a constant pressure

Specifications

| Temperature Range | RT to 1100 °C |

|---|---|

| Measurement Atmosphere | Vacuum, Inert gas, Air |

Utility

| Floor space | Approx.W2000 x D700 (mm) |

|---|---|

| Weight | Approx.180kg |

| Power | 1Φ AC200V 4.8kVA 1Φ AC100V 2kVA 1Φ AC100V 1.5kVA |

| Cooling water | 7L/min or more, 0.2MPa or more |

Option

- Pressure control system 1set

- Sample vessel, collection tube for sublimation refining simulation 1set

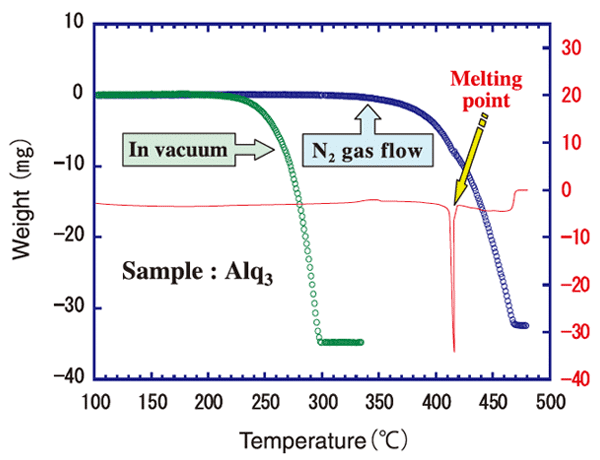

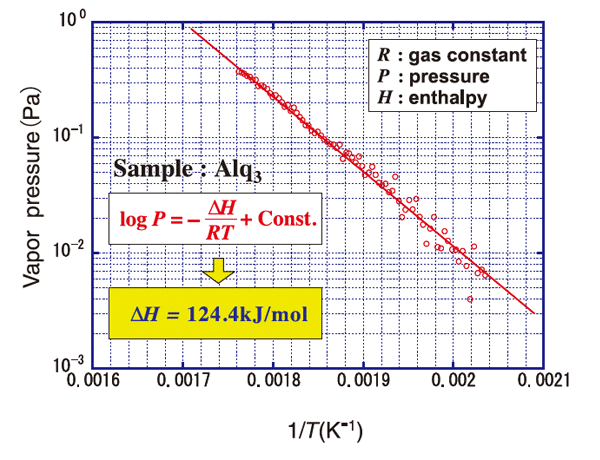

Measurement example

Analysis example

Analysis service by using this product

Related product

Infrared lamp heating system RTP-mini

Thermal Flow Rate Evaluation System for Low Thermal Resistance Multilayer Substrates F-CAL

Ultra High Precision Thermal Expansion Measurement System by Laser Interferometer SuperLIX

Polymeric Thermoelectric Sheet Evaluation System ZEM-d

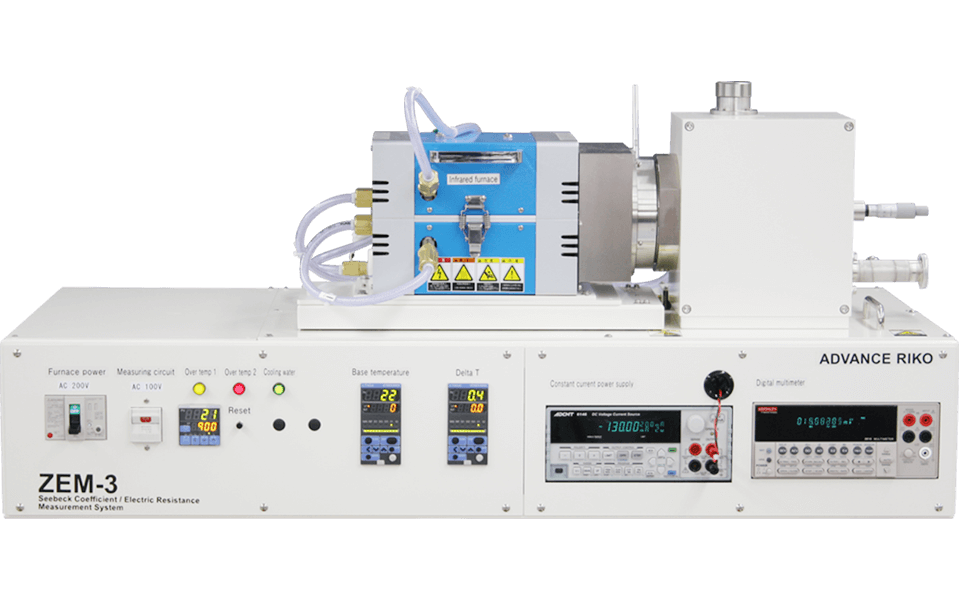

Seebeck Coefficient / Electric Resistance Measurement System ZEM-3 series

Atmospheric Thermoelectric Module Evaluation System F-PEM

Vapor Pressure Evaluation System VPE-9000<vacuum thermobalance> Contact form

The information that you enter will only be used to provide you with a response. However, when you request that we mail you a catalog or other materials, please understand that the shipper specified by ADVANCE RIKO may use only the information necessary to send those materials, such as your name and address.

Please check our privacy policy for more details.