Analysis of thermoelectric measurement

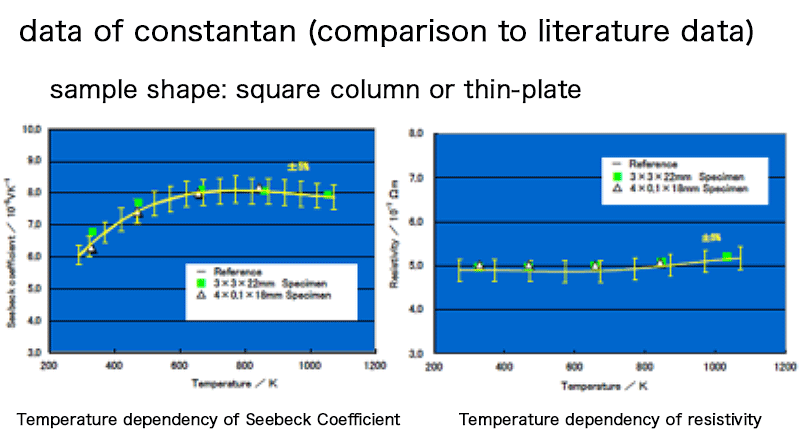

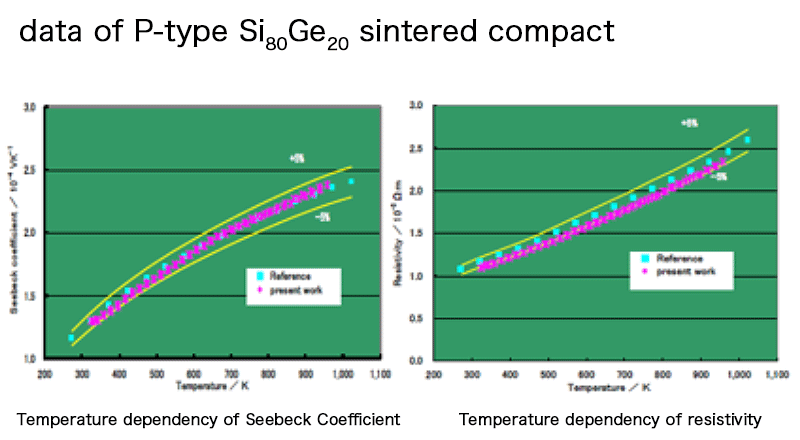

Measure seebeck coefficient, electric resistance and thermal conductivity in order to get performance index of a material itself.

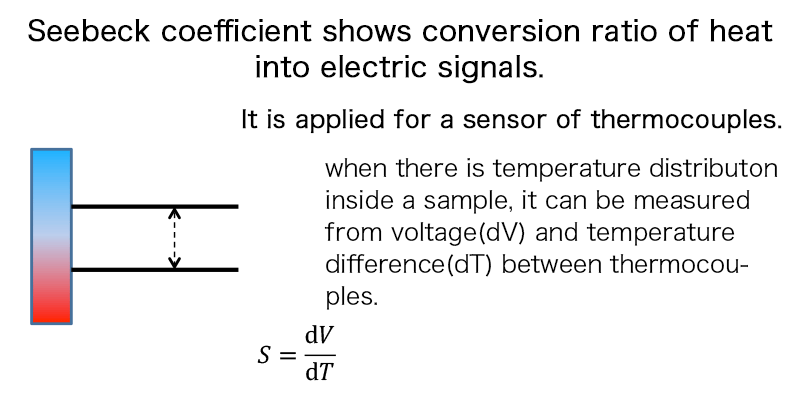

Measure seebeck coefficient

Electric resistance・Seebeck coefficient

| temperature range | atmosphere | sample size, shape |

|---|---|---|

| room temperature~800℃ | low-pressure helium gas | solid square or φ2~4㎜ length 5㎜~22㎜ High resistance (1KΩ ~ 10MΩ) |

| thin-plate thickness 30~500μm width 2~4mm length 10~16mm High resistance (1KΩ ~ 10MΩ) * Consult us when it is film type. |

suitable for this measurement: Seebeck Coefficient / Electric Resistance Measurement System ZEM-3 series

Electric resistance・Seebeck coefficient

| temperature range | atmosphere | sample size, shape |

|---|---|---|

| 200°C Max. (High temperature side on a sample) | In air, inert gas | Cross-section area: Max.20mm-dia. Thickness: 0.01~20mm |

suitable for this measurement: Polymeric Thermoelectric Sheet Evaluation System ZEM-d

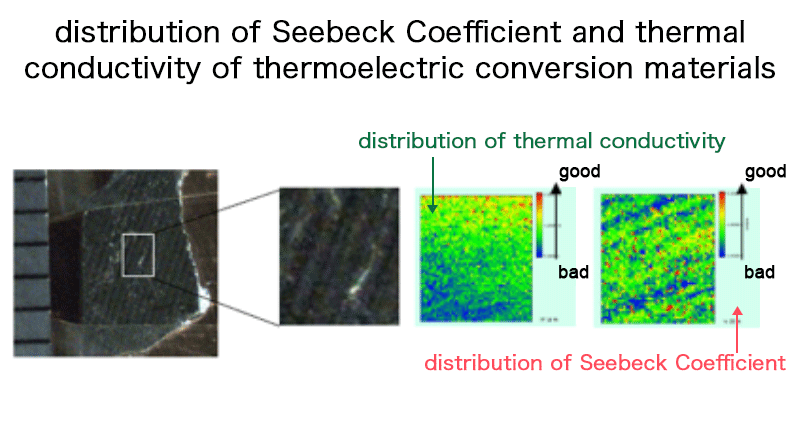

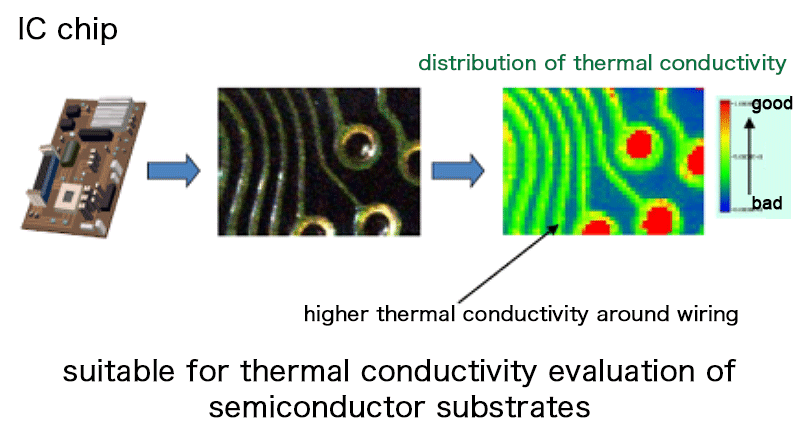

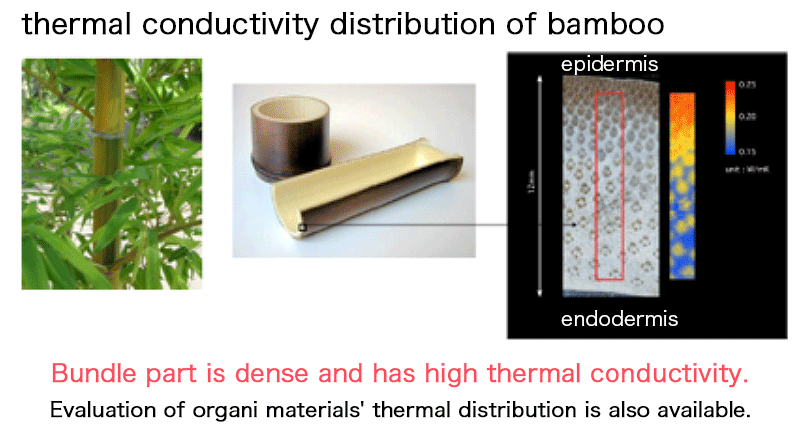

suitable for this measurement: Scanning Thermal probe Micro-image STPM-1000

power conversion efficiency

Apply temperature difference to thermoelectric module and then evaluate its power generation efficiency from current dependency on power generation amount and heat flow.

power generation amount・conversion efficiency・amount of the current

| temperature range | atmosphere | sample size, shape |

|---|---|---|

| 50~600℃ * Please consult. |

air | square 40mm thickness 5~30mm |

suitable for this measurement: Atmospheric Thermoelectric Module Evaluation System F-PEM

power generation amount・conversion efficiency・amount of the current

| temperature range | atmosphere | sample size, shape |

|---|---|---|

| 50~500℃ | vacuum | square 2~10㎜ thickness 2~15㎜ |

suitable for this measurement: Thermoelectric Conversion Efficiency Evaluation System for Small modules