Scanning Thermal Probe Micro-image

STPM-1000

2 dimensional distribution of Seebeck coefficient and thermal conductivity measurement system by thermal probe

STPM-1000 is used for evaluating Seebeck coefficient and thermal conductivity simultaneously. Simple evaluation of thermoelectric materials is possible by simultaneous evaluations of seebeck coefficient and thermal conductivity. The thermal conductivity distribution evaluation of functionally graded materials, multilayer substrates and organic materials is also possible. STPM-1000 is expected to use materials evaluation as a basic tool.

Applications

- Distribution evaluation of thermoelectric materials

- Material development and homogeneity valuation of thermoelectric materials

- Homogeneity evaluation of inorganic materials, polymer materials, crystalline materials

- Thermal conductivity evaluation of mounting

- materials (Printed circuit boards, multilayer boards etc)

Features

- Just in 10 seconds for 1 point distribution measurement

- Available to perform a mapping analysis at a pitch of 20μm.

- Improve better accuracy of thermal conductivity by calibrating with a standard sample

- Customizable to □ 50 mm sample (max.)

This system was developed based on a joint patent #5252543 with national institute of advanced industrial science and technology (AIST)

Specifications

| Type | STPM-1000 |

|---|---|

| Measurement temperature | RT + 5 °C |

| Maximum sample size | Square 20 mm × Thickness 5 mm |

| Accuracy of Seebeck coefficient | ± 10 % (by single bulk sample with thickness 1mm) |

| Accuracy of thermal conductivity | ± 50 % (by single bulk sample with thickness 1mm) |

| Measurement time at one point | less than 10 s. |

| Local resolution | 20 μm |

| Resolution of position control | 1 μm |

| Sample moving distance | x-axis 50 mm, y-axis 50 mm, z-axis 10 mm |

| Power supply | AC 100V 15 A (excluding PC) |

| External dimensions | W510 × D650 × t460 (mm) |

| Weight | Approx. 70kg |

| Space requirement | Approx. W1200 × D900 (mm) for table |

※Thermal conductivity of unknown sample can be estimated by reference sample of known thermal conductivity and comparison calibration.

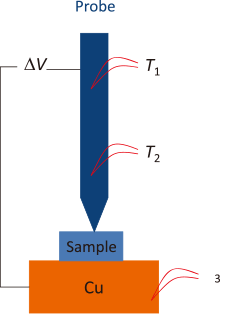

Measurement principle

Seebeck coefficient

Calculate from voltage difference (ΔV) and temperature difference (ΔV) beteween temperature at contact point Tcp and T3.

(Tcp is calculated from T1 and T2.)

Thermal conductivity

Calculate from T1 - T2.

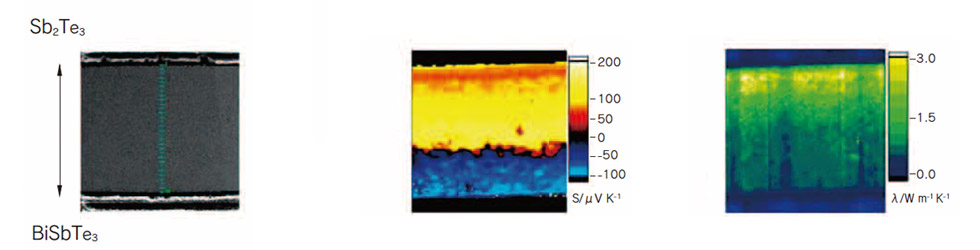

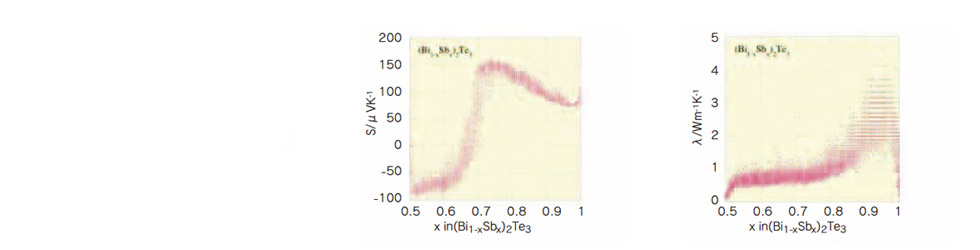

Measurement examples

Seebeck coefficient and thermal conductivity distribution and composition dependence of Seebeck coefficient and thermal conductivity of (Bi1-xSbx)2Te3(0.5 Seebeck coefficient distribution Thermal conductivity distribution Composition dependence of Seebeck coefficient Composition dependence of thermal conductivity

Applications

- Simple performance evaluation of thermoelectric materials

- Thermal property distribution evaluation of functionally graded materials

- Homogeneity evaluation of inorganic materials, polymer materials and crystalline materials

- Defect assessment of practical materials (Print substrate, multilayer substrate etc.)

Utility

| Power supply | AC 100V 15A (excluding PC) |

|---|---|

| External dimensions | W510 × D650 × t460 (mm) |

| Weight | Approx. 70kg |

| Space requirement | Approx. W1200 × D900 (mm) for table |

Analysis service by using this product

Related product

Infrared lamp heating system RTP-mini

Thermal Flow Rate Evaluation System for Low Thermal Resistance Multilayer Substrates F-CAL

Ultra High Precision Thermal Expansion Measurement System by Laser Interferometer SuperLIX

Polymeric Thermoelectric Sheet Evaluation System ZEM-d

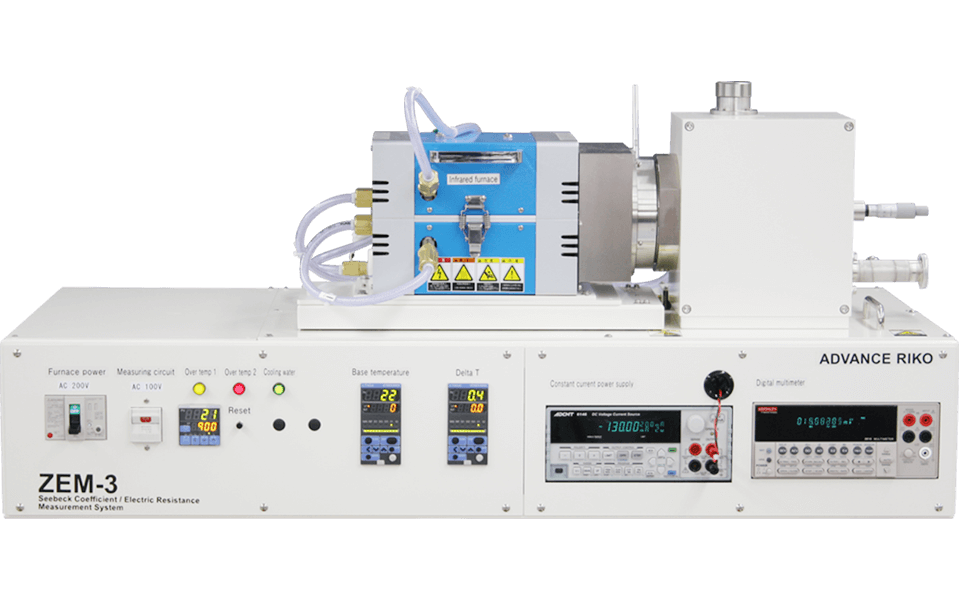

Seebeck Coefficient / Electric Resistance Measurement System ZEM-3 series

Atmospheric Thermoelectric Module Evaluation System F-PEM

Scanning Thermal Probe Micro-image STPM-1000 Contact form

The information that you enter will only be used to provide you with a response. However, when you request that we mail you a catalog or other materials, please understand that the shipper specified by ADVANCE RIKO may use only the information necessary to send those materials, such as your name and address.

Please check our privacy policy for more details.