Arc-Plasma method nano-particle Deposition System

APD series

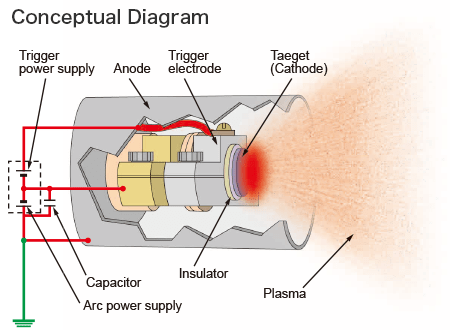

New nanoparticle deposition system using pulse vacuum arc discharge

Pulse vacuum arc deposition is a unique technique to deposit ultrathin films and nanoparticles by generating metal ions in a simple process. This system can achieve high in terms of film flatness and particle fineness, which is impossible with other systems.

Applications

- APD-S (Substrate deposition model)

Metal film (magnetism, Plasmon, protection film) - APD-P (Powder support model)

Fuel cell catalyst by use of nanoparticles, exhaust gas catalyst, photocatalyst, VOC dispersed catalyst, carbon nanotube catalyst, Plasmon

Features

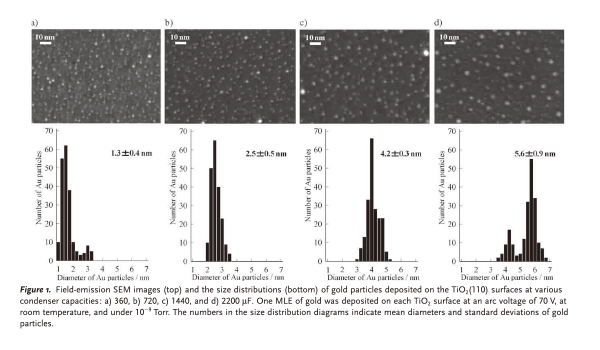

- Capable of selecting freely nanoparticle diameter from approx.1.5nm to 6 nm by changing condenser capacity

- Any conductive materials (targets) can be converted into plasma.

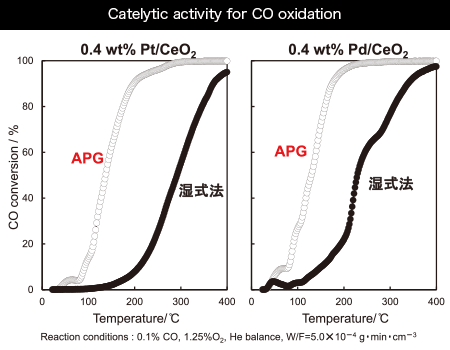

*Specific resistance of a target: 0.01Ωcm or less - Nanoparticles supported by this system show highly active catalytic effect compared with ones produced through wet process.

Specifications

| Model | APD-S | APD-P |

|---|---|---|

| Sample size | Substrate φ 2 inch |

Powder Vessel size (inside dimension) φ 95 × H 30 (mm) with stirring mechanism |

| Standard deposition numbers | 1 | 1 |

Mechanism

Five Futures

- The system can select nano-particle diameter within the range of approx. 1.5nm to 6nm by changing condenser capacity.

- The system can make any material plasmatic in case they are electrically-conductive materials(target).

*Specific resistance for target is 0.01 ohm cm or less - The system can readily generate oxide and nitride by changing atmosphere.

Also, when graphite is discharged in H2 gas, it generates UNCD(Ultrananocrystalline diamond). - The nano-particles supported by the system shows active catalytic effects as compared with wet process.

- Model APD-P supports nano-particles to powders.

Model APD-S supports nano-particles to 2-inch substrate.

*The above-mentioned 1, 3 and 4 depend on literatures.

Quoted literatures: “Ministry of Education, element strategic project achievement” by Professor Machida at Kumamoto University

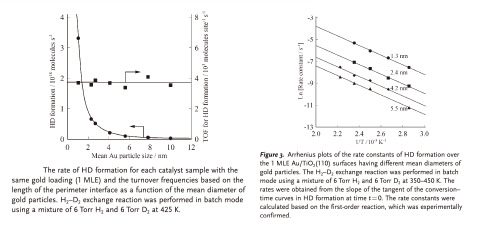

Relation between condenser capacity and nano-particle size

Chemistry in National Institute of Advanced Industrial Science and Technology

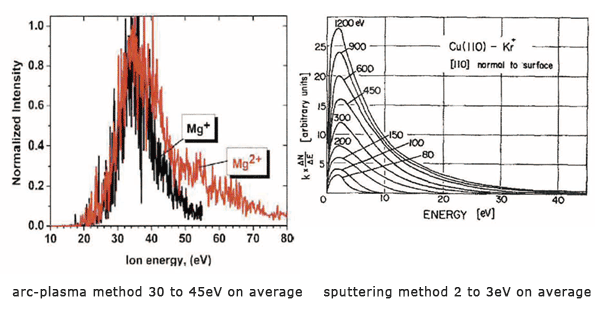

The difference in energies largely contributes to the generation and function of nano-particles.

(The vertical axis is no unit of quantity required due to relative values.)

Quoted literatures: Arc-plasma J. Appl. Phys. 101(2007)043304 SputterJ. Appl. Phys. 35(1964)1819

Publication List

- C-dopand

MBE growth mode and C incorporation of GeC epilayers on Si (001) substrates using arc plasma gun as a novel C cource

Motoki Okinaka*, Yasumasa Hamana1, Takashi Tokuda, Jun Ohta, Masahiro Nunoshita

Journal of Crystal Growth 249 (2003) 78-86 - Characterisation of NPs by APD

Ultra-small platinum and gold nanoparticles by arc plasma deposition

Sang Hoon Kima,∗, Young Eun Jeonga, Heonphil Haa, Ji Young Byuna, Young Dok Kimb

Applied Surface Science 297 (2014) 52–58

10.1016/j.apsusc.2014.01.072 - HRTEM analyses of the platinum nanoparticles prepared on graphite particles using coaxial arc plasma deposition

Kun'ichi Miyazawa, Masaru Yoshitake, Yumi Tanaka

J Nanopart Res (2017) 19:191

10.1007/s11051-017-3895-6 - Characterisation of NPs by APD in ionic liquids

Temperature-independent formation of Au nanoparticles in ionic liquids by arc plasma deposition

Yoshikiyo Hatakeyama a,1, Satoshi Kimura b, Tatsuya Kameyama c, Yoshiaki Agawa d, Hiroyuki Tanaka d, Ken Judai a, Tsukasa Torimoto c, Keiko Nishikawa b,⇑

Chemical Physics Letters 658 (2016) 188–191

10.1016/j.cplett.2016.06.044 - CNT catalyst

High-density horizontally aligned growth of CNT with Conanoparticles deposited by Arc discharge plasma method

D. Phokharatkul,1 Y. Ohno,1,a H. Nakano,2 S. Kishimoto,1 and T. Mizutani1

APPLIED PHYSICS LETTERS 93, 053112 2008

10.1063/1.2969290 - Robust Noise Modulation of Nonlinearity in Carbon Nanotube Field-Effect Transistors

Toshio Kawahara , Satarou Yamaguchi, Kenzo Maehashi1, Yasuhide Ohno1, Kazuhiko Matsumoto1, and Tomoji Kawai1

Japanese Journal of Applied Physics 49 (2010) 02BD11

10.1143/JJAP.49.02BD11 - High-Rate Growth of Films of Dense, Aligned Double-Walled Carbon Nanotubes Using Microwave Plasma-Enhanced Chemical Vapor Deposition

Mineo HIRAMATSU, Hidetoshi NAGAO1, Masaki TANIGUCHI1, Hiroshi AMANO1, Yoshinori ANDO1 and Masaru HORI2

Japanese Journal of Applied Physics Vol. 44, No. 22, 2005, pp. L 693–L 695

10.1143/JJAP.44.L693 - Combinatorial

Combinatorial Arc Plasma Deposition of Thin Films

Seiichi HATA , Ryusuke YAMAUCHI1, Junpei SAKURAI1 and Akira SHIMOKOHBE1

Japanese Journal of Applied Physics Vol. 45, No. 4A, 2006, pp. 2708–2713

10.1143/JJAP.45.2708 - Combinatorial Search for Low Resistivity Pd–Cu–Si Thin Film Metallic Glass Compositions

Ryusuke YAMAUCHI , Seiichi HATA1, Junpei SAKURAI and Akira SHIMOKOHBE

Japanese Journal of Applied Physics Vol. 45, No. 7, 2006, pp. 5911–5919

10.1143/JJAP.45.5911 - Searching for Novel Ru-Based Thin Film Metallic Glass by Combinatorial Arc Plasma Deposition

Junpei SAKURAI , Seiichi HATA1, Ryusuke YAMAUCHI, and Akira SHIMOKOHBE

Japanese Journal of Applied Physics Vol. 46, No. 4A, 2007, pp. 1590–1595

10.1143/JJAP.46.1590 - Dye sensitizing

Transparent conductive oxide layer-less dye-sensitized solar cells consisting of floating electrode with gradient TiOx blocking layer"

Yoshikazu Yoshida,1 Shyam S. Pandey,1 Kenshiro Uzaki,1 Shuzi Hayase,1,a Mitsuru Kono,2 and Yoshihiro Yamaguchi2

APPLIED PHYSICS LETTERS 94, 093301 2009

10.1063/1.3089845 - Exhaust gas catalyst

CO oxidation activity of thermally stable Fe–Cu/ CeO2 catalysts prepared by dual-mode arc-plasma process

Satoshi Hinokuma,abc Noriko Yamashita,a Yasuo Katsuhara,a Hayato Kogamia and Masato Machida*ab

Catal. Sci. Technol., 2015, 5, 3945

10.1039/c5cy00370a - Nanoparticle catalyst preparation using pulsed arc plasma deposition

Satoshi Hinokuma,abc Satoshi Misumi,a Hiroshi Yoshidab and Masato Machida*ab

Cite this: Catal. Sci. Technol., 2015, 5, 4249

10.1039/c5cy00636h - Effect of thermal ageing on the structure and catalytic activity of Pd/CeO2 prepared using arc-plasma process

Satoshi Hinokuma,ab Hiroaki Fujii,a Yasuo Katsuhara,a Keita Ikeueab and Masato Machida*ab

Catal. Sci. Technol., 2014, 4, 2990

10.1039/c4cy00291a - Pd Fe/CeO2 bimetal catalysts prepared by dual arc-plasma deposition

Satoshi Hinokuma1, Yasuo Katsuhara, Eriko Ando, Keita Ikeue, Masato Machida∗

Catalysis Today 201 (2013) 92– 97

10.1016/j.cattod.2012.03.063 - Structure and catalytic property of supported rhodium catalysts prepared using arc-plasma

Satoshi Hinokumaa,b, MadokaOkamotob, ErikoAndob, KeitaIkeueb, MasatoMachidab,∗

Catalysis Today xxx (2011) xxx–xxx

10.1016/j.cattod.2011.03.008 - A nanometric Rh overlayer on a metal foil surface as a highly efficient three-way catalyst

Satoshi Misumi1, Hiroshi Yoshida1,2, Satoshi Hinokuma1,2,3, Tetsuya Sato4 & Masato Machida1,2

10.1038/srep29737 - Subnano-particle Ce catalyst prepared by pulsed arc-plasma process

Satoshi Hinokuma a,b,c, Hayato Kogami a, Noriko Yamashita a, Yasuo Katsuhara a, Keita Ikeue a,b, Masato Machida a,b,*

Catalysis Communications 54 (2014) 81–85

10.1016/j.catcom.2014.05.025 - Arc Plasma Processing of Pt and Pd Catalysts Supported on c-Al2O3 Powders

S. Hinokuma Æ K. Murakami Æ K. Uemura Æ M. Matsuda Æ K. Ikeue Æ N. Tsukahara Æ M. Machida

Top Catal (2009) 52:2108–2111

10.1007/s11244-009-9387-x - Fuel cell

Pt−Ni Nanoparticle-Stacking Thin Film: Highly Active Electrocatalysts for Oxygen Reduction Reaction

Naoto Todoroki,* Takashi Kato, Takehiro Hayashi, Shuntaro Takahashi, and Toshimasa Wadayama

ACS Catal. 2015, 5, 2209−2212

10.1021/acscatal.5b00065 - The d-Band Structure of Pt Nanoclusters Correlated with the Catalytic Activity for an Oxygen Reduction Reaction

Eishiro Toyoda,*,† Ryosuke Jinnouchi,† Tatsuya Hatanaka,† Yu Morimoto,† Kei Mitsuhara,‡ Anton Visikovskiy,‡ and Yoshiaki Kido‡

J. Phys. Chem. C 2011, 115, 21236–21240

10.1021/jp206360e - 2D Platinum Network ORR Catalyst on Carbon and Niobium Oxide Hybrid Support

C. Xu1, J. Yang1, B. L. Pence1, K. Gath1, P. Pietrasz1, M. Sulek1, K. Sun2, E. Sohm3, G. Meng3

ECS Transactions, 64 (3) 181-189 (2014)

10.1149/06403.0181ecst - Preparation of Pt/C Catalyst by Coaxial Arc Plasma Deposition for Polymer Electrolyte Membrane Fuel Cells

Yoshiaki Agawa,a,b,z Masayuki Kunimatsu,c Takeshi Ito,d Yasutaka Kuwahara,a and Hiromi Yamashitaa

ECS Electrochemistry Letters, 4 (10) F57-F60 (2015)

10.1149/2.0091510eel - Gold catalyst

Hydrogen Dissociation by Gold Clusters

Tadahiro Fujitani,* Isao Nakamura, Tomoki Akita, Mitsutaka Okumura, and Masatake Haruta

Angew. Chem. Int. Ed. 2009, 48, 9515 –9518

10.1002/anie.200905380 - Graphene layer growth catalyst

Graphene layer growth on silicon substrates with nickel film by pulse arc plasma deposition

K. Fujita,a) K. Banno, H. R. Aryal,b) and T. Egawa

APPLIED PHYSICS LETTERS 101, 163109 (2012)

10.1063/1.4761474 - Hydrogen peroxide solution

High performanceofhydrogenperoxidedetectionusingPt nanoparticles-dispersedcarbonelectrodepreparedbypulsedarc plasma deposition

Takeshi Ito a,n, MasayukiKunimatsu a, SatoruKaneko a, YasuoHirabayashi a, MasayasuSoga a, Yoshiaki Agawa b, KojiSuzuki c

Talanta 99(2012)865–870

10.1016/j.talanta.2012.07.048 - Magnetic thin film

Magnetic properties of Nd–Fe–B thick film magnets prepared by using arc deposition

M. Nakano, M. Sahara,a K. Yamawaki, T. Yanai, and H. Fukunaga

JOURNAL OF APPLIED PHYSICS 107, 09A744 2010

10.1063/1.3348233 - Nanocomposite Nd-Fe-B/α-Fe Thick-Film Magnets Prepared by Vacuum Arc Deposition

Masaki Nakano, Tomoaki Tsutsumi, Takeshi Yanai, and Hirotoshi Fukunaga

IEEE TRANSACTIONS ON MAGNETICS, VOL. 50, NO. 11, NOVEMBER 2014 - Photo catalyst

Improved Inactivation Effect of Bacteria: Fabrication of Mesoporous Anatase Films with Fine Ag Nanoparticles Prepared by Coaxial Vacuum Arc Deposition

H. Oveisi, S. Rahighi, X. J., Y.i Agawa, A. Beitollahi, S. Wakatsuki, and Y. Yamauchi

10.1246/cl.2011.420 - Prox catalyst

Support Effect of Arc Plasma Deposited Pt Nanoparticles/TiO2 Substrate on Catalytic Activity of CO Oxidation

Kamran Qadir,†,§ Sang Hoon Kim,‡,§ Sun Mi Kim,† Heonphil Ha,‡ and Jeong Young Park*,†

J. Phys. Chem. C 2012, 116, 24054−24059

10.1021/jp306461v - Catalytic activity of Au TiO2 and Pt TiO2 nanocatalysts prepared with arc plasma deposition under CO oxidation

Sang Hoon Kima,1, Chan-Ho Jungb,c,1, Nruparaj Sahub,c, Dahee Parkb,c, Jung Yeul Yund, Heonphil Haa, Jeong Young Parkb,c,∗

Applied Catalysis A: General 454 (2013) 53– 58

10.1016/j.apcata.2012.12.049 - Thermoelectric element

Fabrication by Coaxial-Type Vacuum Arc Evaporation Method and Characterization of Bismuth Telluride Thin Films

M. UCHINO,1 K. KATO,2 H. HAGINO,1 and K. MIYAZAKI1,3

Journal of ELECTRONIC MATERIALS, 2013 TMS

10.1007/s11664-012-2438-2 - TiN film

Synthesis of TiN thin film on diamond surface for ferrous metal contacts by a new atom beam method

Hiroshi Kinoshitaa,∗, Shunsuke Yamamotob, Hideaki Yatanib, Tetsuo Nakaic, Nobuo Ohmaeb

Applied Surface Science 258 (2012) 3002– 3006

10.1016/j.apsusc.2011.11.026 - Ultrananocrystalline Diamond/Hydrogenated Amorphous Carbon Composite Films

Structural and Physical Characteristics of Ultrananocrystalline Diamond/Hydrogenated Amorphous Carbon Composite Films Deposited Using a Coaxial Arc Plasma Gun

T. Yoshitake, Y. Nakagawa, A. Nagano, R. O., H. Setoyama1, E. Kobayashi1, K. Sumitani1, Y. Agawa and K. Nagayama

Jpn. J. Appl. Phys. 49 (2010) 015503

Analysis service by using this product

Related product

Infrared lamp heating system RTP-mini

Thermal Flow Rate Evaluation System for Low Thermal Resistance Multilayer Substrates F-CAL

Ultra High Precision Thermal Expansion Measurement System by Laser Interferometer SuperLIX

Polymeric Thermoelectric Sheet Evaluation System ZEM-d

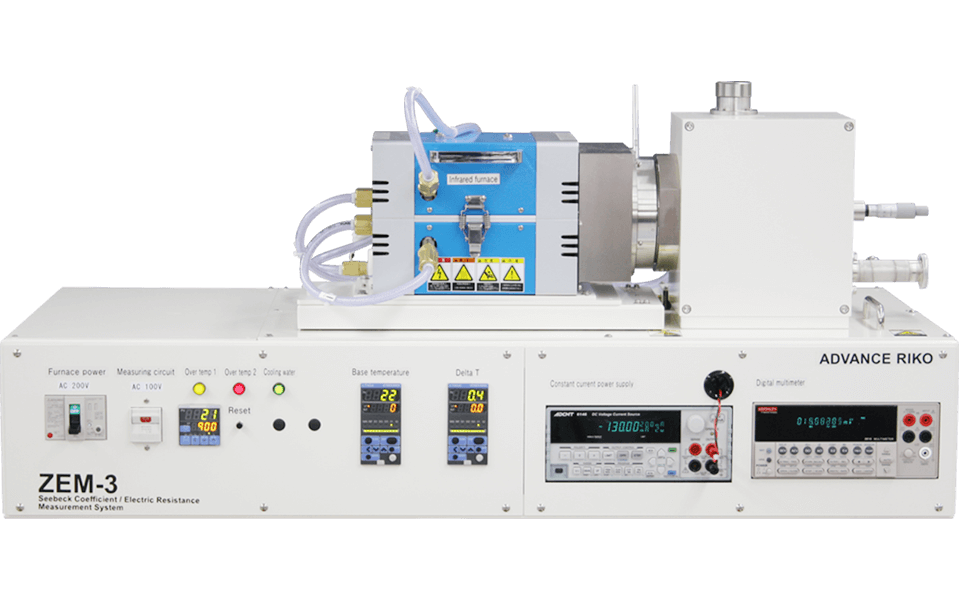

Seebeck Coefficient / Electric Resistance Measurement System ZEM-3 series

Atmospheric Thermoelectric Module Evaluation System F-PEM

Arc-Plasma method nano-particle Deposition System APD series Contact form

The information that you enter will only be used to provide you with a response. However, when you request that we mail you a catalog or other materials, please understand that the shipper specified by ADVANCE RIKO may use only the information necessary to send those materials, such as your name and address.

Please check our privacy policy for more details.