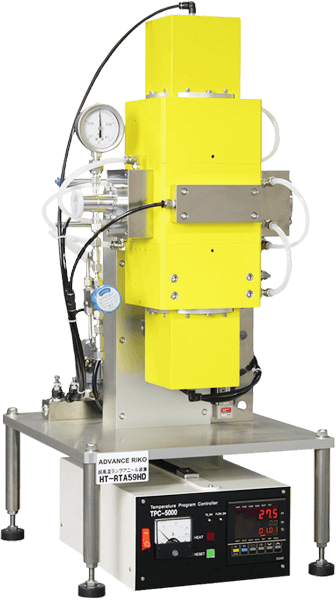

High Temperature Rapid Thermal Annealing System

HT-RTA59HD

Heating a small piece of sample up to 1800°C just in 10 seconds.

HT-RTA59HD is a desktop-type lamp annealing system which enables a small piece of sample to heat up to 1800°C (Ultrahigh temperature zone) just in 10 seconds with high reflection efficiency by spot focused heating.

Applications

- SiC (Power device) oxide film formation to activation

- Heat treatment furnace for high-melting point material

- Sintering and baking furnace

- Local heating impact test furnace

- Crystal growth test furnace (Zone melting)

Features

- Capable of heating a small piece of sample (□ 15 mm) up to 1800°C (Ultra-high temperature zone) just in 10 seconds.

- High reflection efficiency with high-power spot focused heating

- Desktop-type compact design

- Infrared lamp heating method enables clean-heating to minimize dust and gas generation

- It is available to easily input outer signal or temperature program setting from your PC and display the temperature data during heating on the monitor.

Specifications

| Temperature range | RT ~ 1800 °C |

|---|---|

| Sample dimension | □15 × t1 (mm) |

| Heating atmosphere | Various gas flow |

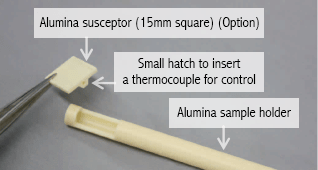

| Thermocouple | JIS B φ 0.3 (W-Re is available) |

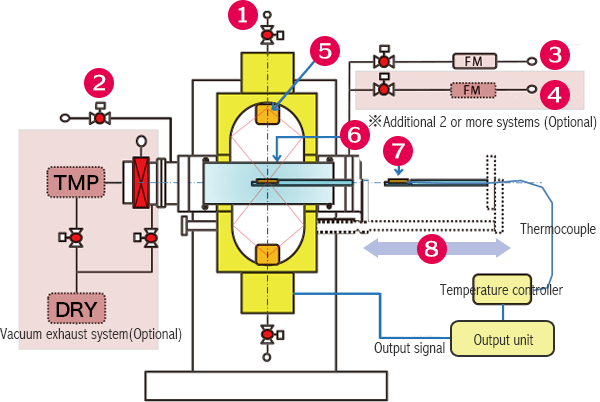

System diagram

- ❶ For lamp cooling Air GAS INLET

- ❷ GAS OUTLET

- ❸ N2 GAS INLET

- ❹ Ar GAS INLET

- ❺ Lamp

- ❻ Transparent quartz protective tube

- ❻ Transparent quartz protective tube

- ❽ Slider to move the sample into/out of the furnace (Manual operation)

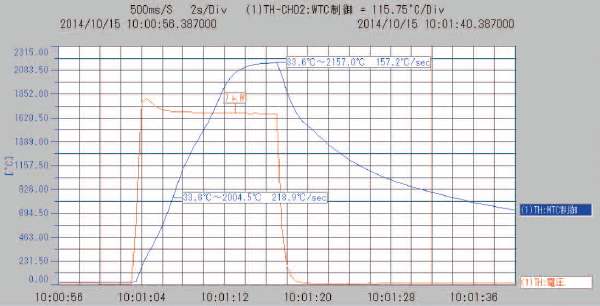

Heating property

Maximum achieving temperature

The power supply : 7kW (max.)Measurement : W-Re thermocouple

Heating atmosphere : N2 1L/min

Attainment Temperature : 2157℃ (Approx 200℃/sec heating up to 2000℃)

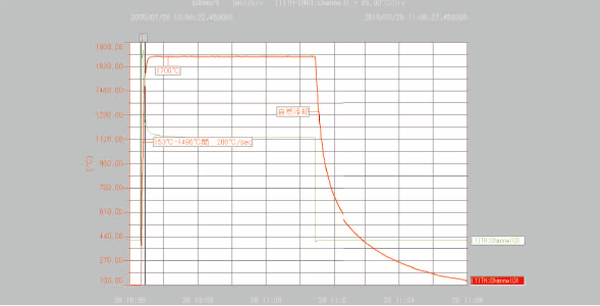

Rapid heating control

Temperature recipe : 200℃/s holding time 5 min.Heating atmosphere : N2 100cc/mm

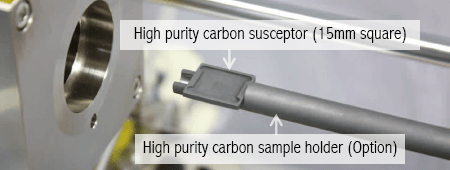

Sample holder : High purity carbon

Sample Susceptor : High purity carbon

Sample holder and susceptor

Utility

| Power requirements | AC 200V, single phase 8kW |

|---|---|

| Cooling water | 0.3MPa Approx 5L/min |

| Lamp cooling gas | Dry air Approx 200L/min |

| Outside dimensions (mm) | Approx W410 x D450 x H840 (excluding protrusion) |

| Weight | Approx 45kg |

Option

- Vacuum exhaust system (RP, DRY, TMP etc.)

- Gas piping system (From 2nd system)

- Cooling water circulator

- Cooling air generator system

- Handy spot welder (HS-9000)

- Handy arc welder (HA-1H)

Analysis service by using this product

Related product

Infrared lamp heating system RTP-mini

Thermal Flow Rate Evaluation System for Low Thermal Resistance Multilayer Substrates F-CAL

Ultra High Precision Thermal Expansion Measurement System by Laser Interferometer SuperLIX

Polymeric Thermoelectric Sheet Evaluation System ZEM-d

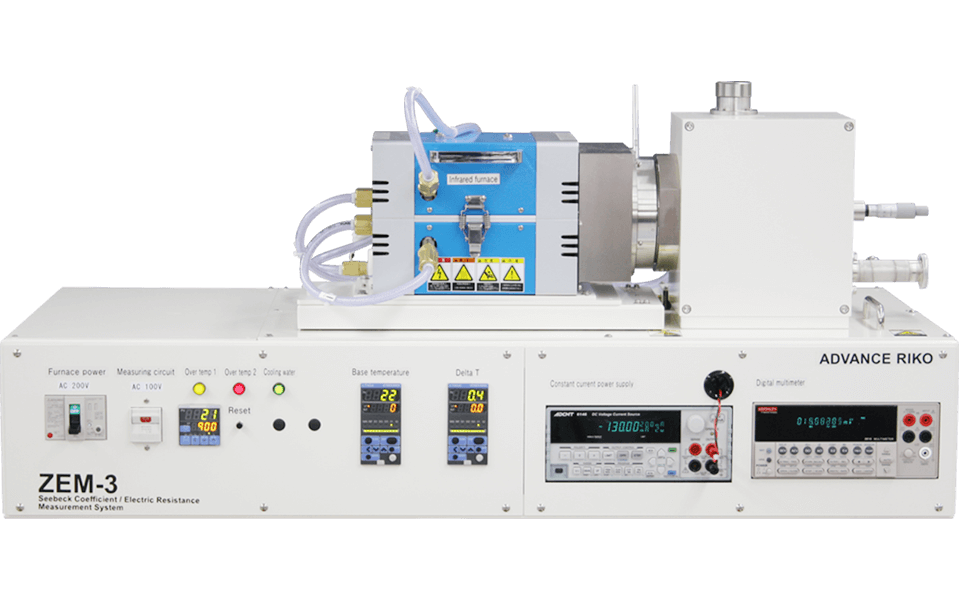

Seebeck Coefficient / Electric Resistance Measurement System ZEM-3 series

Atmospheric Thermoelectric Module Evaluation System F-PEM

High Temperature Rapid Thermal Annealing System HT-RTA59HD Contact form

The information that you enter will only be used to provide you with a response. However, when you request that we mail you a catalog or other materials, please understand that the shipper specified by ADVANCE RIKO may use only the information necessary to send those materials, such as your name and address.

Please check our privacy policy for more details.