Rapid Thermal Annealing System

RTA series

High speed heat treatment from 2 inches to 300 mm 10 seconds until retention.

Infrared lamp heating is the method which can take advantage of its features of High energy density, Near infrared rays, High heat responsiveness, Temperature controllability, and Cold wall method.

We’re meeting the needs of our customers with supplying RTA Series, which can control the process recipe (heating and cooling) and gas type with its flow amount. The system is suitable for finding the best heating conditions.

Applications

- Activation annealing after ion implantation.

- Oxide film deposition annealing.

- Ohmic electrode alloying.

- Crystallization annealing of PZT, SBT and other ferroelectric thin films.

- Si wafer donor-killer processing.

- Silicide formation, salicide formation.

- Heat treatment of light emitting elements, semiconductor laser substrates.

- Ultra-shallow junction formation.

- Ferroelectric capacitor deposition.

- Gate oxide film formation.

Features

- Capable of 200°C/s max. flash annealing.

- Compatible with C to C robot transport systems.

- Can be linked with semiconductor manufacturing equipment.

- Zone output control of lamps to perform uniform heat treatment of multi-wafers.

Specifications

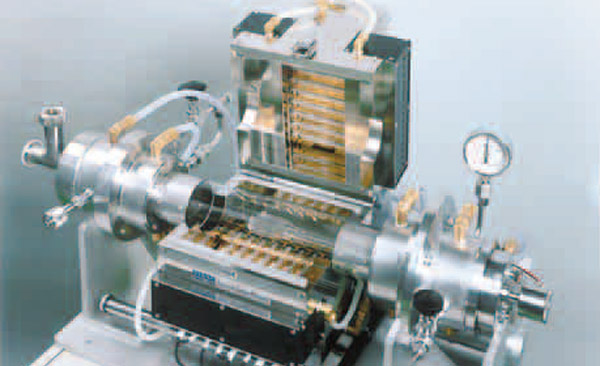

RTA-4000 CtoC

RTA-2000

RTA-6000

| Model | Sample Size | Temperature Range | Max. Heating Rate | Atmosphere |

|---|---|---|---|---|

| RTA-2000 | φ2-inch × 1 piece | RT ~ 1000°C | 100 °C/sec | In Air, Vacuum, Static gas, Gas flow |

| RTA-4000 | φ3 ~ 4-inch × 1 piece | 200 °C/sec | ||

| RTA-6000 | φ4 ~ 6-inch × 1 piece | 200 °C/sec | ||

| RTA-8000 | φ6 ~ 8-inch × 1 piece | 200 °C/sec | ||

| RTA-12000 | φ300mm × 1 piece | 100 °C/sec |

For other specification requirements, such as Single wafer processing, Flash annealing, C to C type, Other heating temperature, Gas type, Vacuum degree, please feel free to contact us.

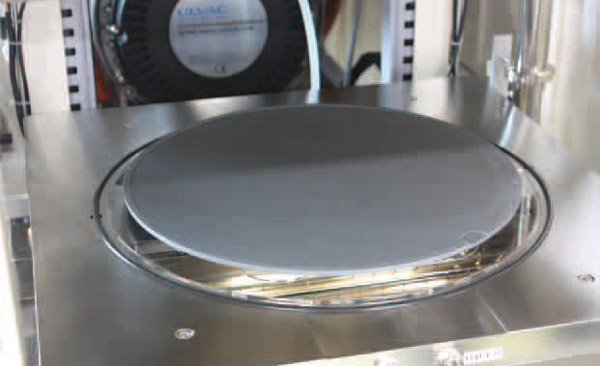

C to C Robotic transfer system During transfering Si wafer

Related product

Infrared lamp heating system RTP-mini

Thermal Flow Rate Evaluation System for Low Thermal Resistance Multilayer Substrates F-CAL

Ultra High Precision Thermal Expansion Measurement System by Laser Interferometer SuperLIX

Polymeric Thermoelectric Sheet Evaluation System ZEM-d

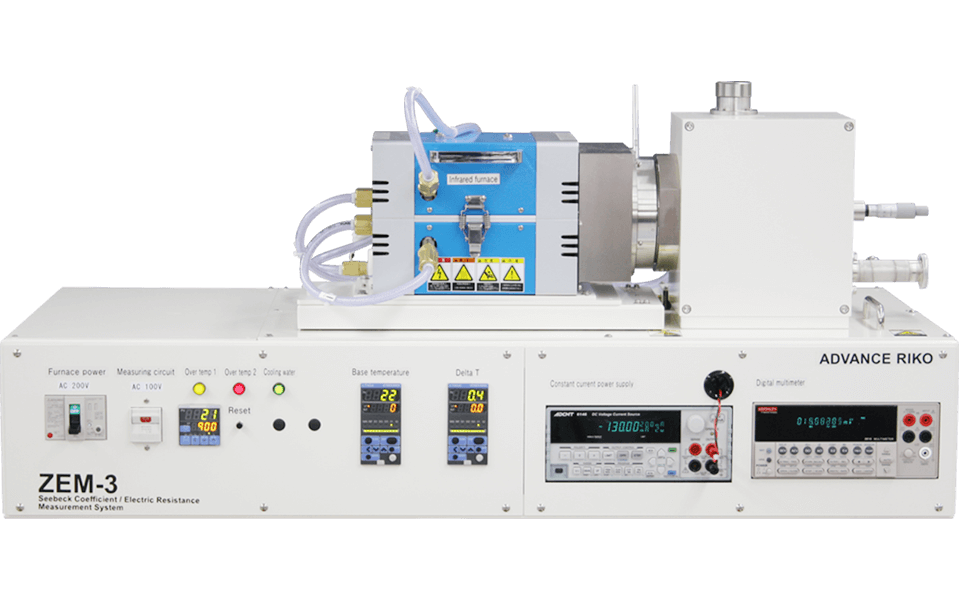

Seebeck Coefficient / Electric Resistance Measurement System ZEM-3 series

Atmospheric Thermoelectric Module Evaluation System F-PEM

Rapid Thermal Annealing System RTA series Contact form

The information that you enter will only be used to provide you with a response. However, when you request that we mail you a catalog or other materials, please understand that the shipper specified by ADVANCE RIKO may use only the information necessary to send those materials, such as your name and address.

Please check our privacy policy for more details.