2-Omega Method Nano Thin Film Thermal Conductivity Meter

TCN-2ω

Thermal conductivity evaluation for a nano thin film at normal direction

TCN-2ω is the world’s only system which can measure thermal conductivity for a nano thin film at normal direction.

Applications

- Best suited for evaluation of thermal conductivity of thin film required for thermal design.

Low-K insulating film, Organic thin film, Thin film of thermoelectric materials - Development on an insulating film and improvement of its heat dissipation

- Application evaluation to thermoelectric thin films

Features

- Available to measure thermal conductivity of thin film (20 ~ 1000nm thickness) deposited on a substrate

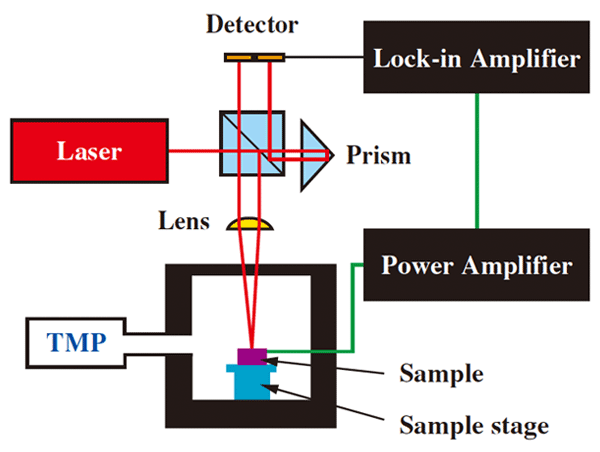

- Actualize the measurement of detecting temperature change by thermo-reflectance method

- Simply pre-treated for a sample

Specifications

| Measurement Properties | RT |

|---|---|

| Sample size | W10 × L10 ~ 20 × t0.3 ~ 1 (mm) (Substrate) |

| Measurement Atomosphere | Vacuum |

Measurement principle

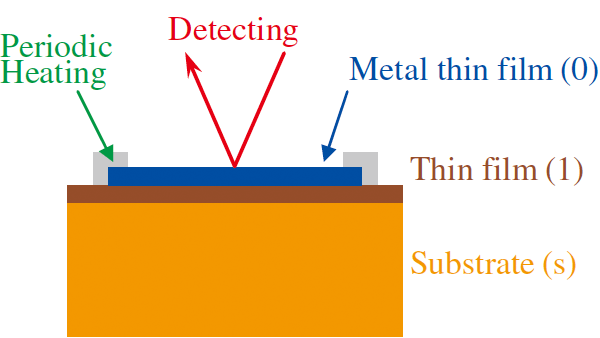

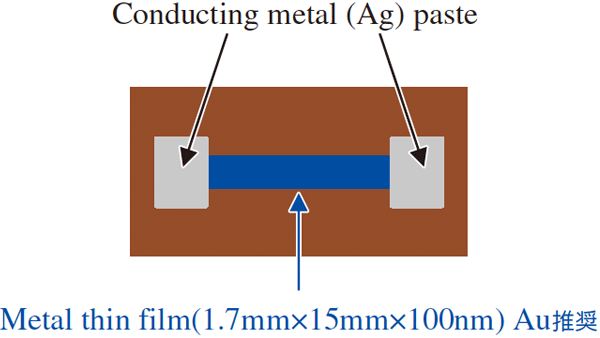

Metal thin film is heated by the periodic heating method with the basic frequency ( f / Hz). As a result, the response frequency with the thermal energy, 2 f / Hz, is equal to two times as large as the basic one. In the case of the film composed of metal thin film (0) – thin film (1) – substrate (s) as shown in Figure, the temperature increase T(0) on the upper surface for the metal thin film can be calculated on the basis of one-dimensional heat conduction model. Assuming that the energy completely arrived at the bottom substrate, T(0) is following the equation,

(λ / W m-1 K-1, C / J K-1 m-3, q/ W m-3, d / m , ω (=2πf ) / s-1)

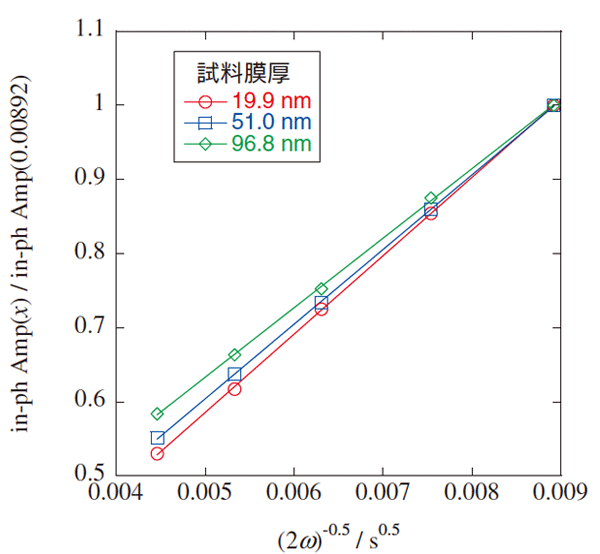

We note that the real part (in-phase amplitude) contains the information for the thin film. Assuming that the thermal energy completely arrives at the bottom substrate, the in-phase

amplitude is proportional to (2ω)-0.5. Thermal conductivity for the

thin film (λ1) is estimated from

(m:slope, n: intercept)

SiO2film (20-100nm)- Si substrate

| d1 / nm | 19.9 | 51.0 | 96.8 |

|---|---|---|---|

| λ1 / Wm-1 K-1 | 0.82 | 1.12 | 1.20 |

A patent and a standard

Measurement method of thermophysical properties(Japan Patent No.5426115)Analysis service by using this product

Related product

Infrared lamp heating system RTP-mini

Thermal Flow Rate Evaluation System for Low Thermal Resistance Multilayer Substrates F-CAL

Ultra High Precision Thermal Expansion Measurement System by Laser Interferometer SuperLIX

Polymeric Thermoelectric Sheet Evaluation System ZEM-d

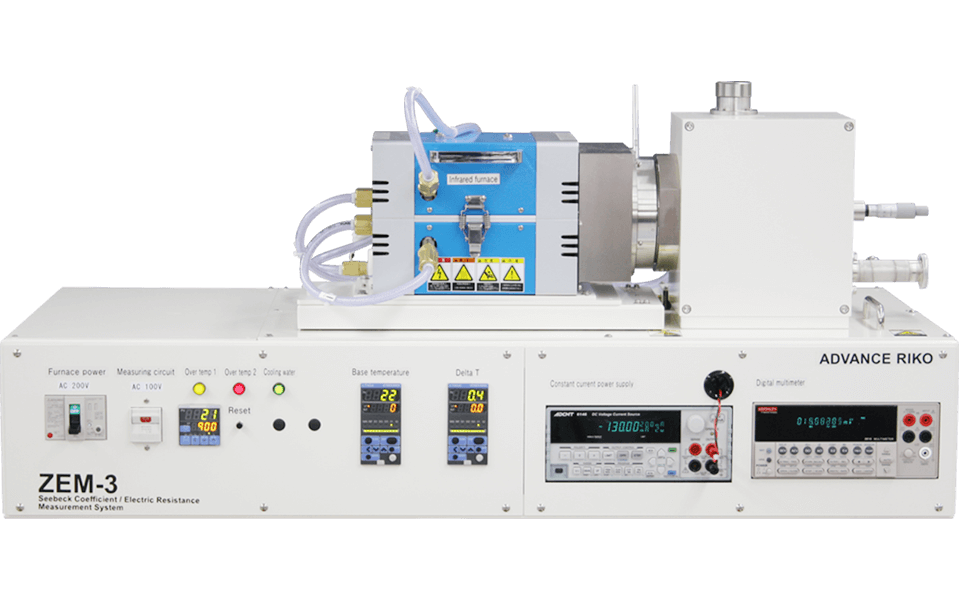

Seebeck Coefficient / Electric Resistance Measurement System ZEM-3 series

Atmospheric Thermoelectric Module Evaluation System F-PEM

2-Omega Method Nano Thin Film Thermal Conductivity Meter TCN-2ω Contact form

The information that you enter will only be used to provide you with a response. However, when you request that we mail you a catalog or other materials, please understand that the shipper specified by ADVANCE RIKO may use only the information necessary to send those materials, such as your name and address.

Please check our privacy policy for more details.