Ceramics Product list

We offer the products that enables thermal evaluation accoding to each process from the acquisition of basic physical properties to quality inspection such as thermal shock test, thermal cycle test, heating observation test, thermal conductivity measurement, thermal expansion measurement, electrical resistance measurement, insulation resistance measurement etc for various ceramics (oxides, carbides, nitrides, etc.) materials, glass materials, and composite hybrid materials. Recently, the high-precision expansion measurement of laser interferometry type for the needs of zero-expansion materials has become increasingly necessary on the quality evaluation of products.

-

Ultra High Precision Thermal Expansion Measurement System by Laser Interferometer SuperLIX

The world of expansion with accuracy of 1×10-8/K or less Thermal expansion measurement with the world-class ultra high accuracy *as a commercial measurement system Application case Development of zero-expansion materials Development of negative thermal expansion material and anode materials Development of standard materials Development of materials for actuator

-

Laser Flash Method Thermal Constant Measurement System TC-1200RH / TC-9000 series

Thermal conductivity measurements covering a wide range of materials not only thermoelectric materials but also metals, ceramics, carbon etc. The systems measure 3 thermal constants (Thermal diffusivity, Specific heat capacity, Thermal conductivity) for uniform solid materials such as thermoelectric materials, ceramics, carbon, Metal, etc

-

Electric Heat Resistance Measurment System EHR series

Temperature dependency measurement of insulator samples This system can measure the temperature dependency of insulators like ceramics, plastics and glass.

-

Thermodilatometer DL-9000 / DLY-9000 series

Dedicated thermal expansion measurement system for bulk materials Dedicated linear expansion and contraction measurement system for various solid samples

-

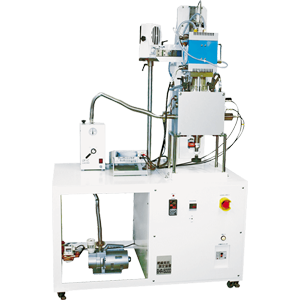

Robotic Thermal Dilatometer DLY-9000 ROBOT

Labour-saving quality management with fully automatic and unattended operationuality control. This system was developed for the purpose of standardizing the measurement and saving labor in quality management. With superior repeatability, safety measures for unattended operation and chart function, this system is most suitable for quality management.

-

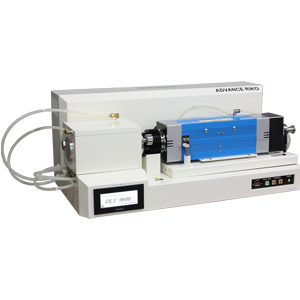

Thermal Expansion Measurment Systemby Laser Interferometer LIX-2 series

High-accuracy measurement of thermal expansion with a minimum resolution of 1nm This is a laser thermal expansion measurement system with ultra-high sensitivity developed by the use of the latest optical techniques. This system is suitable to be used as a calibration system for a standard thermal dilatometer, also to measure absolute thermal expansion measurements of unknown samples. This system is compliant with JIS R3251-1995, Measuring method of the linear thermal expansion coefficient for low expansion glass by laser interferometry.

-

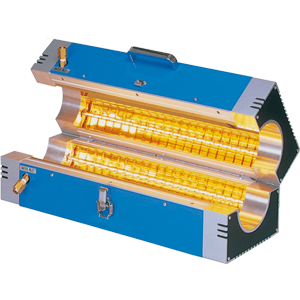

Infrared Gold Image Furnace RHL-E/VHT/P series

Meeting customer needs with infrared lamp heating Infrared Gold Image Furnaces can be used in many fields for research and development or as production equipment. We’re meeting the needs of our customers from high speed heating to wide area heating.

-

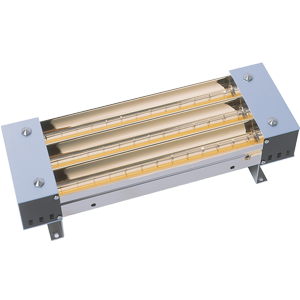

Infrared Gold Image Furnace Ps, Pss series

Useable in wide fields from carbon nanotube growth equipment to production equipment. The flat plate reflected infrared heating furnace can be used for applications such as a 2-inch to 300 mm diameter wafer lamp annealing system or a production baking furnace.

-

Programmable Temperature Controller TPC-5000 series

Temperature controller capable of supporting high-speed heating with good precision. This programmable temperature controller can support not only Infrared Gold Image Furnaces that require a fast response during high-speed heating , but also low-speed heating furnaces. It features high functionality and high performance in a compact package and meets your needs with a low price and many accessories.

-

Rapid Thermal Annealing System RTA series

High speed heat treatment from 2 inches to 300 mm 10 seconds until retention. Infrared lamp heating is the method which can take advantage of its features of High energy density, Near infrared rays, High heat responsiveness, Temperature controllability, and Cold wall method. We’re meeting the needs of our customers with supplying RTA Series, which can control the process recipe (heating and cooling) and gas type with its flow amount. The system is suitable for finding the best heating conditions.