Metals and steel Product list

We offer various products which meet your demands for various metal materials and composite metal material evaluation ① Heat treatment by rapid heating control (quenching/tempering/annealing), visualization of brazing, thermal fatigue test, thermal cycle test, and crystal transformation ② Wettability evaluation ③ Thermal expansion measurement of cast/composite bonded metal ④ Electrical resistance measurement ⑤ Thermal resistance measurement of composite metal/laminate ⑥ Thermal conduction measurement ⑦ Alloying of different metals etc,

-

Rapid Thermal Annealing System RTA series

High speed heat treatment from 2 inches to 300 mm 10 seconds until retention. Infrared lamp heating is the method which can take advantage of its features of High energy density, Near infrared rays, High heat responsiveness, Temperature controllability, and Cold wall method. We’re meeting the needs of our customers with supplying RTA Series, which can control the process recipe (heating and cooling) and gas type with its flow amount. The system is suitable for finding the best heating conditions.

-

Low Cost Infrared Lamp Heating System for R&D RTP-6

80°C/s high speed annealing possible at low cost. This infrared lamp heating system with parabolic type reflectors can heat uniformly a wafer of the size up to 6 inches. It is capable of high-speed heat treatment, the most available for the research and development of heat treatment process. Silicide formation in individual semiconductor process and process annealing of compound semiconductor are available.

-

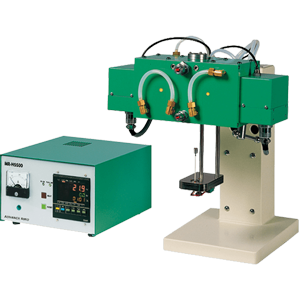

Mini Lamp Annealer MILA-5000 series

MILA-5000 series The MILA-5000 series can perform high speed heating, high speed cooling, and clean heating, which are characteristics of the Infrared Gold Image Furnace. It can heat materials under adjustable atmospheres and combines a temperature controller and variable atmosphere chamber into a single low-cost infrared lamp heating system. Heating operations can be run by a PC connected via USB and data can be easily managed. MILA-5000UHV Based on the MILA-5000-P-N (high temperature type), the MILA-5000UHV was born as a……

-

Mini Lamp Annealer with air-cooling system MILA-700AR

ini Lamp Annealer with no use of cooling water As the cooling method is air-cooling with a fan, the heating operations can be easily started with just a wall outlet.

-

Simplified Infrared Lamp Heating System SSA series

Simplified system with Infrared Gold Image Furnace and a quartz chamber. A low-cost heating system consist of an Infrared Golc Image Furnace and quartz chamber including a sample holder.

-

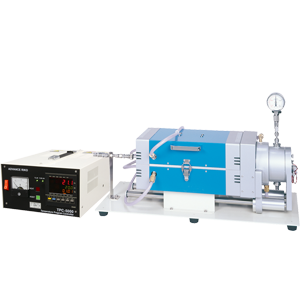

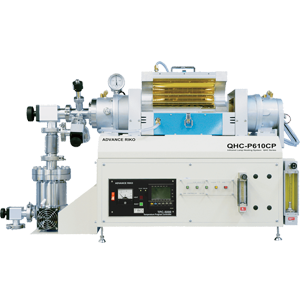

Infrared Lamp Heating System QHC series/Variable Atmosphere Lamp Heating System VHC series

Helping process development From solar cells to compound semiconductors. Combining an Infrared Gold Image Furnace and temperature controller, the QHC/VHC series is a compact high speed heating/ cooling system equipped with a quartz heat treatment chamber. The system is customizable to your needs.

-

Spot Focused Infrared Gold Image Furnace System series

Heating up to 1800°C in just 1 min. For ultra-high temperature vacuum heat treatment MIRO series is a compact spot focused Gold Image Furnace which enables to heat up to 1800°C with extremely high reflection efficiency in combination with single or double type chambers.

-

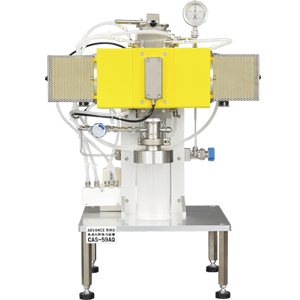

Rapid Heating / Water Quenching System CAS-59AQ

Rapid heating and quenching of materials This system is capable of water quench after heating. The maximum temperature is 1800°C under various atmospheres.

-

High Temperature Rapid Thermal Annealing System HT-RTA59HD

Heating a small piece of sample up to 1800°C just in 10 seconds. HT-RTA59HD is a desktop-type lamp annealing system which enables a small piece of sample to heat up to 1800°C (Ultrahigh temperature zone) just in 10 seconds with high reflection efficiency by spot focused heating.

-

Continuous Annealing System for Steel Sheet CAS series

Easy determination of transformation point of steel sheets The CAS series achieves high-speed heating and cooling with the use of an Infrared Gold Image Furnace, direct temperature control of the samples, and easy atmosphere production. This system makes it possible to precisely achieve thermal treatment simulations of processes for steel and iron materials that had been previously difficult. Supports general purpose heat treatment tests to process heat treatment simulation tests of materials such as steel sheets, steel plates, stainless steel……